Main auxiliary and service production examples. Auxiliary production. Auxiliary production costs. Main and auxiliary production: what is the difference

Is it possible for the costs of repairing fixed assets recorded by the company on balance sheet account 23 to be immediately attributed to the balance sheet account? 90.2? Or is it necessary first at 20, and then at the cost of sales?

Yes, it is possible if the support unit provided services (performed work) to other organizations. Make the posting at the time of sale of these services (works). Debit 90-2 Credit 23. In all other cases, close the turnovers on account 23 to production accounts (20, 25, 26, 29). In this case, the procedure for writing off account 23 is determined in accounting policy for accounting purposes.

The rationale for this position is given below in the materials of the "Glavbukh Systems" vip-version

Ancillary production is designed to ensure the normal operation of the main production by providing it with a certain type of service or performing work. In addition, they can provide services (perform work) and other auxiliary divisions of the organization (for example, service industries and farms). In some cases, auxiliary industries provide services (perform work) on the side. In addition, auxiliary production can produce spare parts, production and household equipment, etc.

Accounting

Cost accounting auxiliary production conducted on account 23 "Auxiliary production".

On the debit of account 23, all expenses are accumulated that are associated with the activities of auxiliary production: material costs, labor costs, depreciation deductions and other expenses. These costs, as well as in the main production, are divided into direct and indirect (general production and general economic). The procedure for classifying specific costs as direct or indirect should be determined independently based on the organization of production, industry characteristics.

Recognize direct costs as they arise on the debit of account 23 in correspondence with accounts for accounting for costs of auxiliary production. In this case, do the wiring:

Debit 23 Credit 10 (02, 05, 29, 69, 70 ...)

- the direct costs of auxiliary production are taken into account.

This procedure follows from the instructions to the chart of accounts.

Consider general production costs as part of ancillary production costs in one of the following ways.

1. Using account 25 "General production costs". In this case, such expenses must first be taken into account in the debit of this account, and then at the end of the month, write off to account 23. In this case, make the entries:

Debit 25 Credit 10 (02, 05, 69, 70 ...)

- Reflected overhead costs;

Debit 23 Credit 25

- taken into account general production costs related to ancillary production.

For more information on how to account for general production costs, see How to write off general production and general expenses.

2. Bypassing account 25 "General production costs". In this case, take into account the costs of servicing auxiliary production directly on account 23. Use this option only when it is possible to clearly define the belonging of such expenses to auxiliary production. In this case, do the wiring:

Debit 23 Credit 10 (02, 05, 69, 70 ...)

- reflects general production costs, which can be clearly identified as belonging to auxiliary production.

This procedure follows from the instructions to the chart of accounts.

General business expenses should be included in the cost of ancillary production (that is, on account 23) if the organization does not immediately recognize them in the cost of goods sold (that is, it does not write off at the end of the month to account 90-2). For more on this, see How to write off general production and general expenses. In this case, do the wiring:

Debit 26 Credit 10 (02, 05, 69, 70 ...)

- reflected general expenses;

Debit 23 Credit 26

- taken into account general operating costs related to ancillary production.

This procedure follows from the instructions to the chart of accounts.

After the services (work) are rendered (performed), write off their cost (that is, the expenses recorded in the debit of account 23) from the credit of account 23 to the accounts for accounting for production costs or financial results depending on who is their consumer (Instruction to the chart of accounts). In this case, make postings in correspondence:

- with account 20 "Main production" or account 25 "General production costs" - if the services (work) were provided (performed) to ensure the work of the main production:

Debit 20 (25) Credit 23

- the cost of services rendered (work performed) of auxiliary production was taken into account as part of the cost of main production;

- with account 26 "General business expenses" - if auxiliary production provided the work of the management departments of the organization:

Debit 26 Credit 23

- the cost of the services provided (work performed) of the auxiliary production was taken into account as part of the costs of the management departments of the organization;

- with account 29 "Service industries and farms" - if the services (work) were provided (performed) to service industries and farms:

Debit 29 Credit 23

- the cost of services rendered (work performed) of auxiliary production was taken into account as part of the costs of servicing industries and farms;

- with account 90 "Sales" or account 91 "Other income and expenses" - if auxiliary production provided services (performed work) to other organizations. Make postings at the time of sale of these services (works):

Debit 62 Credit 90-1 (91-1)

- reflected income from the sale of services (works) of auxiliary production;

Debit 90-2 (91-2) Credit 23

- the cost of services rendered (work performed) of auxiliary production was taken into account as part of expenses that reduce income from their sale;

Debit 90-3 (91-2) Credit 68 subaccount "Calculations for VAT"

- VAT was charged on the cost of sold services (works) (if this operation is subject to VAT).

For more information on how to take into account income and expenses when selling services (works), see How to reflect the implementation of works (services) in accounting and taxation.

This procedure follows from the instructions to the chart of accounts.

In all cases, the cost of services (work) is calculated based on the actual costs of their provision (performance), which are collected on the debit of account 23 (Instructions to the chart of accounts). In this case, use the method of accounting for costs and calculating the cost price, which is enshrined in the accounting policy for accounting purposes. *

If the auxiliary production simultaneously provided services (performed work) to several divisions of the organization (for example, the boiler house of the organization heats production workshops and premises occupied by management structures (accounting, director, etc.)), their cost must be distributed. This is necessary in order to know what the cost of auxiliary production services will increase the costs of the corresponding division of the organization. That is, what amount will be charged to the debit of accounts 20, 25, 26, 29. Develop the procedure for distributing the costs of auxiliary production yourself. For example, expenses can be distributed:

· In proportion to the area of \u200b\u200bthe premises that are occupied by the relevant divisions of the organization, served by auxiliary production;

In proportion to the salary of employees working in the relevant divisions of the organization, served by auxiliary production, etc.

Fix the selected option in the accounting policy for accounting purposes (clause 7 PBU 1/2008). *

Ancillary production can produce spare parts, production and household equipment, etc. In this case, consider this property in the composition of materials (clause 2 PBU 5/01). Determine their cost based on the actual costs associated with their production (manufacturing), which are collected according to the debit of account 23 (clause 64 of the Methodological Instructions approved by order of the Ministry of Finance of Russia dated December 28, 2001 No. 119n, clause 7 PBU 5/01, Instructions for the chart of accounts). Consider manufactured spare parts, inventory and other materials for:

· Account 10 "Materials" - if the organization reflects the receipt of materials at the actual cost;

· Account 15 "Procurement and purchase of materials" – if the organization accounts for the receipt of materials at discount prices.

Moreover, the possibility of using in in this case account 10 (15) fix in the accounting policy for accounting purposes. This must be done, since the Instruction to the Chart of Accounts provides for another option for accounting for property made on our own: on account 43 "Finished products". Make entries on account 10 (15, 43) on the basis of the invoice requirement in the form No. M-11, which you draw up when transferring materials to the warehouse (clause 57 of the Methodological Instructions approved by order of the Ministry of Finance of Russia dated December 28, 2001 No. 119n).

The receipt of materials (spare parts, inventory, etc.) manufactured by auxiliary production, reflect the wiring:

Debit 10 (15, 43 ...) Credit 23

- materials (spare parts, inventory, etc.) manufactured by auxiliary industries have arrived at the warehouse.

For more information on how to account for the receipt of materials using account 10 or 15, see How to issue, reflect in accounting and taxation of receipt of materials.

The balance at the end of the month on account 23 will show the value of work in progress (Instructions to the chart of accounts). Such a situation may arise when the work or services at the end of the month are not completed (for example, the repair of production equipment has not been completed) (clause 64 of the Regulation on accounting and reporting).

Elena Popova,

state Adviser of the Tax Service of the Russian Federation, I rank

Ancillary industries are those that perform certain work or provide services for the main sectors of capital construction, social services and other areas of the organization.

Ancillary production includes:

1. Mechanical repair shops.

2. Automobile and horse-drawn transport.

3. Cartage.

4. Services for electricity, water and gas supply.

5. Services for the operation of refrigeration units.

The products of auxiliary industries are works and services consumed in the main industries (crop production, animal husbandry, ancillary industrial production) or in other areas of activity.

Thus, auxiliary industries are created to service other industries and services.

The main objectives of accounting for the costs of auxiliary production are:

1. Correct and accurate determination of the total cost of their maintenance and maintenance of the auxiliary work of the services provided for each production.

2. Correct distribution and write-off of the cost of work performed and services rendered to their consumers.

To account for the costs of auxiliary production, account 23 "Auxiliary production" is used - active, calculation, on the debit of which the costs of auxiliary production are collected, and on credit they are written off to the accounts of consumers of services of auxiliary production.

Account 23 "Auxiliary production" has the following sub-accounts:

23 \\ 1 - repair shops;

23 \\ 2 - repair of buildings and structures;

23 \\ 3 - road transport;

23 \\ 4 - energy production (farms);

23 \\ 5 - water supply;

23 \\ 6 - heat supply;

23 \\ 7 - gas supply;

23 \\ 8 - animal-drawn transport;

23 \\ 9 - construction of temporary (not title) structures;

23 \\ 10 - other auxiliary production.

The costs of auxiliary production on account 23 "Auxiliary production" are accounted for according to the following nomenclature of articles:

1. Labor costs.

2. Social contributions.

3. Raw materials and materials, including:

3.1 Petroleum products.

3.2 Spare parts.

3.4 And others.

5. Works and services.

6. Expenses of funds.

7. Costs for the organization of production and management.

8. Other costs.

Analytical accounting of the costs of auxiliary production is carried out in the production report on auxiliary production, maintenance and operation of the machine and tractor fleet of form 18 V. This document is filled in on the basis of primary documents grouped in cumulative statements, which are opened for each type of auxiliary production.

Synthetic accounting of costs for ancillary production is kept in the log-order 10 of the agro-industrial complex, the data into which is transferred monthly from the production report of form 18B

Synthetic account 23 "Auxiliary production" is opened in the General Ledger Entries in General book on account 23 "Auxiliary production" are made on the basis of the results of the magazine-order 10 agro-industrial complex.

The cost of work performed and services rendered by ancillary industries are monthly written off to the costs of the main production facilities and other consumers of services for the corresponding cost accounting objects for the forecast (planned) s / s unit of these works, services, which at the end of the year is brought to the actual method by writing off the calculation differences red side "(savings), and in case of overspending - by the" additional recording "method. It is possible to assign the services of ancillary production to consumers' accounts immediately according to the actual s / s.

The Chart of Accounts 2012 established that direct costs directly related to the production of products, the performance of work, the provision of services are reflected in account 23 "Auxiliary production" from the credit of accounts 10 "Materials", 60 "Settlements with suppliers contractors", 69 " Calculations by social insurance and support, 70 "Payroll staff" others.

The costs associated with the maintenance and management of structural subdivisions of auxiliary production, recorded on account 25 "General production costs" are written off to the debit of account 23 "Auxiliary production". At the same time, the costs associated with the maintenance and management of structural units of auxiliary production can be accounted for directly on account 23 "Auxiliary production" without preliminary accumulation on account 25 "General production costs"

The actual production of products, work performed, services rendered, produced by auxiliary industries are reflected in the debit of account 20 "Main production", 29 "Serving production and facilities", 43 "Finished products", 10 "Materials", 90 "Income and expenses on current activities "and others and the credit of account 23" Auxiliary production ".

Earlier, in the chart of accounts of 2004, there was a rule that correspondence with the corresponding accounts on the credit of account 23 "Auxiliary production" reflects the amount of actual production completed, works performed and services rendered. In this case, under the actual s / s is meant a complete s / s production. There was only one caveat: the shop and auxiliary production can provide each other with mutual services, which were assessed, as a rule, according to the planned production, works, and services. The resulting difference was credited to the corresponding accounts in proportion to the amount of products released, work performed and services rendered.

According to the chart of accounts of 2012, taking into account the alternative procedure for writing off expenses accounted for on account 25 "General production costs", on account 23 "Auxiliary production" can be formed or with / from products, works, services, based on direct costs and conditionally variable costs , accounted for on account 25 "General production costs" or workshop with / with products, works, services, ie, with / with which includes direct costs and general production costs in full.

Auxiliary production facilities are created at large enterprises in addition to the main technological lines. The costs of auxiliary shops are taken into account in the calculation of the cost of manufactured products. The objectivity of the organization's pricing policy depends on the reliability of accounting for the costs of different groups of production and the literacy of the distribution of invested resources. The procedure for planning and accounting for production costs is governed by the norms of the Order of the Ministry of Industry and Science of January 4, 2003 No. 2.

What concerns auxiliary production

Ancillary production facilities are ancillary units for the main production lines of goods. The range of tasks of auxiliary departments may include:

- supply of energy resources;

- transport service;

- repair and modernization of fixed assets assets;

- creation of tools, parts, fasteners, preparation of spare parts;

- construction of temporary structures;

- extraction of construction raw materials and materials;

- logging work;

- processing of agricultural products.

Ancillary production is needed to ensure the smooth manufacturing process of products and at the same time minimize the cost of additional services in favor of third-party organizations. They are formed in the form of separate workshops, departments and structural subdivisions, can be represented by laboratory centers, calculating stations and computer complexes.

NOTE! Ancillary production does not include enterprise services that are part of departments or structural units (design blocks, chief engineer or chief power engineer).

The characteristic features of an auxiliary production unit are:

- lack of opportunities to manufacture goods from the main product line;

- focus on servicing the main shops and the availability of facilities with equipment for the production of semi-finished products;

- the results of work in auxiliary divisions during the transfer of manufactured semi-finished products to the main technological department are reflected in the calculation of the cost of goods.

Ancillary production is subdivided into the following types:

- Mechanical repair workshops.

- Transport departments.

- Energy economy.

- Refrigeration equipment service divisions.

- Construction of temporary structures at construction sites.

- Warehouse objects.

BTW! Ancillary production with a significant increase in the share of their products in relation to other areas of activity can move into the status of main production units.

Repair shops are responsible for equipment diagnostics, repairs and regular preventive maintenance. The structure of energy structures can include:

- boiler rooms:

- sewer communications;

- water supply system;

- electrical substations;

- transformer installations;

- diesel or gasoline generators;

- gas and electrical networks;

- radio networks;

- furnace equipment;

- electrical equipment repair department.

The energy economy is required for large volumes of energy consumption. The department is responsible for the generation of energy and its supply to the production halls. In transport units, several types are used vehicle:

- external;

- intrashop;

- interdepartmental;

- warehouse.

For continuous transport service, piping systems and conveyor structures can be used.

Warehouse facilities are needed to form stocks of products and semi-finished products, to ensure the safety of goods. Warehouse areas can be used for short-term and long-term placement of commodity groups. By design, warehouse premises are closed, open and semi-closed, supply, general plant, workshop, production, sales. Depending on the functionality, warehouses are classified as either universal or specialized categories.

Ancillary production costs

Clause 4.28 of the Methodological Recommendations approved by Order No. 2 dated 04/01/2003 states that expenditure operations of auxiliary production facilities are accounted for similarly to the methodology of the main shops. Summary estimate calculations should be checked against the volume of work performed, at the next stage the final cost of production is formed.

The distribution of the costs of auxiliary departments among other divisions of the enterprise is carried out as a percentage of the number of self-produced semi-finished products consumed by each department.

The process of reallocating the costs of auxiliary production between other related workshops is necessary to reliably determine the actual cost finished products.

When auxiliary departments implement service functions, all costs are taken into account in the number of general production costs. If the supporting structures are service departments or sales departments, then the costs are included in sales expenses.

The following types of expenses of auxiliary departments can be distributed between the shops of the main production cycle:

- remuneration of employees involved;

- the cost of materials and raw materials transferred to production;

- maintenance of premises.

These indicators can act as criteria for the proportional division of costs. An additional factor by which costs can be divided is the number of employees in departments.

Accounting for auxiliary production

To reflect in accounting the costs incurred by auxiliary production in accordance with the provisions of the Order of the Ministry of Finance No. 94n dated October 31, 2000, synthetic account 23 “Auxiliary production” is used. Debit turnover shows:

- direct costs that have a direct impact on the manufacture of products and the process of providing services;

- indirect type of costs associated with management functions and maintenance of technological lines, losses from defective products.

REMEMBER! The closing balance on the account reflects the monetary value of the production remaining in progress at the reporting date.

Account 23 is attributed by legislators to the group of active accounts, debit transactions are carried out, the credit reflects the output of finished products or the volume of work performed. Analytics is carried out for individual auxiliary industries by opening for each of them its own subaccount.

Postings

Correspondences for accounting of expenses of auxiliary production can be divided into two blocks:

- Reflection of costs.

- Write-off of expenses.

When forming expenses on account 23, the following standard transactions can be used:

- D23 - K10 when reflecting the cost of materials for the manufacture of products;

- D23 - K60 when accepting invoices;

- D23 - K69 is used at the time of calculating insurance premiums for wages;

- D23 - K70 for the amount of remuneration of workers in auxiliary shops;

- D23 - K25, if it is necessary to show in the accounting the general production costs at auxiliary facilities;

- D23 - K26 is used to record general business expenses;

- D23 - D28 costs incurred from rejection are included in the cost price;

- D23 - K02 (04) to reflect the amounts of accrued depreciation on assets of auxiliary departments (fixed assets or intangible assets).

When writing off the expenditure part to the cost of production of the main production, the following entries are made:

- D10 - K23 when reflecting the fact of receipt in the main production of semi-finished products manufactured by auxiliary units;

- D11 - K23 is formed when the weight gain of animals appears, which increases their value;

- D20 - K23 - costs incurred by auxiliary structures are redistributed to the main production;

- D 26 - K23 - the entry is made at the time of writing off the costs incurred to service the management apparatus.

If the products produced by the auxiliary workshops were used for sale to third-party customers, then two transactions are generated at once in the accounting:

- D62 - K90.1 or 91.1 to reflect income;

- D90.2 or 91.2 - K23 for cost accounting as part of the expense base.

VAT payers must additionally make a record of their tax accrual - D90.3 (or 91.2) - K68.

1.2 Main and auxiliary production

Depending on what product is the result of production, production processes are divided into main, auxiliary and service ones.

The central place in this aggregate is occupied by the main production process, as a result of which the raw materials and materials are converted into finished products. For example, in automotive factories, the main process will be the production of blanks for parts, the assembly of assembly units and the complete assembly of cars.

The main production process is divided into three stages: procurement, processing and assembly.

Ancillary PCB is the process of manufacturing products that will be used internally. For example, an auxiliary process in an automobile enterprise includes the manufacture of tools that are used in the processing of car parts, the manufacture of spare parts for equipment repair.

Service PP is a labor process, as a result of which no product is created. It includes transport, warehouse operations, technical control, etc.

Timely and high-quality execution of the main PP largely depends on how the implementation of auxiliary and service processes is arranged, which are subordinated to the task of better provision of the main PP.

1.3 Organization of the technological process for the release of the main products of the enterprise

The organization of production covers all links - from groups of industries and subsectors of the national economy to the workplace.

Within a large machine-building enterprise, three levels of production organization can be distinguished:

1. The organization of the process in the workplace consists in a clear combination of elements of the labor process. For a single-station workplace, the organization of production must ensure the rational correspondence of the basic parameters of the machine, the tool used, the qualification level of the worker, the characteristics of the materials used and the work performed.

With a complex workplace, the organization of production is characterized, first of all, by a clear design of the service system, the order of loading (starting) and removing the finished product, and justification of rational changes in the operating modes of the unit.

2. Intrashop organization of production provides a combination of PPs occurring at workplaces, which are included in one stage of the technological process or in one private PP. Organizationally, this stage of production can be formalized as a site and a workshop.

3. The interdepartmental organization of production includes the implementation of measures for the production of spatial and temporal combination of large stages of PP. Each of these stages is a fairly complete process.

Based on the content and directions of the organization of production, it is possible to formulate its main tasks:

Selection of the most perfect material elements of PP;

Ensuring their full use and rational spatial and temporal combination;

Savings in living labor;

Improving product quality.

The highest form of production organization are automatic production lines, which are a set of machines that, in a certain sequence, automatically perform technological operations for manufacturing products.

The economic efficiency of automatic production lines consists in a sharp increase in labor productivity and product quality, a significant reduction in cost and improvement of other indicators, as well as in facilitating the work of workers whose functions are reduced to machine control.

1.4 Process control in production

Process control depends on the specific structure of a particular enterprise. And also on the way of construction functional system enterprises.

With a centralized method, all management functions are concentrated in the functional departments of the enterprise.

Only line managers were left in the shops and at the sites. To bring the functional apparatus closer to production, a part of this apparatus can be placed on the territory of the workshops that it directly serves. But the employees of this part are subordinate to the head of the general functional department of the enterprise. The centralized system pays off for small production volumes, although it was widely used in the past at all enterprises in "stagnant" times.

With the decentralized method, all service functions are transferred to the shops. Each workshop turns into a closed production unit.

The most effective is the mixed method, which is most widely used in most enterprises. At the same time, issues that can be solved more quickly and better by the shop or business bureau are transferred to their jurisdiction, and the methodological management of functional units and product quality control are performed by the functional departments of the enterprise management apparatus.

Since the main part of the production process takes place directly in the workshop, it has its own process control apparatus. At the head of the workshop is a chief, appointed from among experienced, highly qualified workers and subordinate to the director of the enterprise. He organizes the work of the entire team, carries out measures for the production of mechanization and automation of the production process, the introduction of new technology, and carries out measures of production and labor protection.

To solve specific technical and economic problems in a large workshop, the following are created:

A technical bureau engaged in the improvement of technological production processes, assisting the sites in the development of technological processes and control of technological discipline.

Production dispatching office, which carries out operational production planning and production process control;

A group of mechanics of the workshop, providing equipment maintenance and repair.

The most important link in the production structure of the workshop is the production area, which is headed by a foreman. The foreman is the direct organizer of the production process in his department. He has the right to hire and arrange workers on the site, to release excess workers, to assign wage grades to workers, to reward and fine workers.

Using these rights, the foreman is obliged to ensure the performance of the work facing the site, to prevent defects in production, to ensure the economical use of raw materials and materials, to ensure strict compliance with safety and labor protection.

The widespread use of ACS simplifies the management process. The basis of the ACS is the integrated processing of production and economic information, covering the solution of problems of forecasting, planning and production management using modern means.

2. Project for the organization of a mechanical workshop

2.1 Calculation of the production program

The definition of the production program of the machine shop is based on the needs of the assembly shop, supplies by cooperation and the number of parts used as spare parts. The coefficient taking into account the supply of cooperation is taken equal to 1.2 (Kp). The coefficient taking into account the number of parts used as spare parts for manufactured machines is 1.3 (Kz).

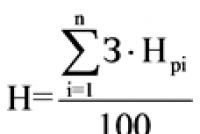

The production program for each product is determined by the formula:

Ni \u003d N Kp Kz (2.1)

where N is the program for the release of the nth product for settlement period, PC.

Ni \u003d 75350 · 1.2 · 1.3 \u003d 117546 (pcs.);

Nzh \u003d 60350 1.2 1.3 \u003d 94146 (pcs.);

Nz \u003d 45750 1.2 1.3 \u003d 71370 (pcs.).

Plan

Introduction

Conclusion

List of sources used

Introduction

In the context of the transition to a market economy, the cost of production is the most important indicator of the production and economic activities of organizations. The calculation of this indicator is necessary to determine the profitability of production and certain types of products; assessing the implementation of the plan for this indicator and its dynamics; implementation of intra-production cost accounting; identifying reserves for reducing the cost of production; determination of prices for products; calculating national income on a national scale; calculation economic efficiency introduction of new equipment, technology, organizational and technical measures; justification of the decision on the production of new types of products and the withdrawal from production of obsolete ones. In domestic practice, accounting for production costs and calculating the cost of production are an integral part of the overall unified accounting system.

If earlier, special attention was paid to cost accounting only at large enterprises, now in a market economy, due to increased competition, complication of production processes, this area of \u200b\u200baccounting is becoming more and more relevant for small and medium-sized enterprises and organizations.

The increasing importance for the enterprise is acquiring the solution of such problems as: information support of the decision-making process; providing a base for pricing; control over the economic efficiency of the enterprise; obtaining performance data; calculation of the valuation for balance sheet items and others.

The relevance of the topic of this course work is determined, first of all, by the objectively significant role of studying the formation of costs of auxiliary industries by types of their income in production in a modern socially oriented market economy, the transition to which is the main vector of the radical reform unfolding in Russia. That is why the formation of costs of auxiliary production is a strategic task of the economic reform policy.

The cost of production is one of the most important economic indicatorscharacterizing the costs of the enterprise associated with the production and sale of its products. Reducing the cost of production is a source of growth in the profitability of enterprises, national wealth and welfare of the country.

1. Auxiliary production. Types of auxiliary industries. Accounting tasks for auxiliary industries

Each enterprise consists of production facilities, workshops, sites, farms, management bodies and organizations for servicing employees of the enterprise.

All production departments of the enterprise can be divided into main, auxiliary and service.

The main is production, during which the main products manufactured by the enterprise are manufactured. The result of the main production in mechanical engineering is the release of machines, apparatus and instruments that make up the production program of the enterprise and correspond to its specialization, as well as the manufacture of spare parts for delivery to the consumer.

Ancillary facilities ensure the smooth running of the main processes. The result is products used in the enterprise itself. Ancillary processes include equipment repair, tool making, steam and compressed air generation, etc.

Service industries carry out the services necessary for the normal functioning of both the main and auxiliary processes. These include, for example, the processes of transportation, warehousing, selection and assembly of parts, etc.

Ancillary production significantly affects the results of the industry. More than two-thirds of the main production maintenance work is carried out by them. In this regard, timely provision of the main production with products and services of auxiliary production is an important condition for increasing output and improving the quality of final products.

Subsidiary farms require high organization, adequate to the level of organization of the main production. Improvement of technology and organization of service creates conditions for the successful operation of the enterprise, the speedy development of new products, the use of advanced technologies and the achievement on this basis of high technical and economic indicators of production.

The rational organization of the work of all auxiliary industries is the most important reserve for stabilizing the main production, increasing the volume of production, further growth in labor productivity and increasing the efficiency of the enterprise.

The organization of accounting for auxiliary industries depends on their type and functions performed, the nature of the technological process and manufactured products, the volume of production, and organizational forms of management.

By types and functions, auxiliary production is divided into six groups: instrumental, repair, energy, transport, packaging, and economic services.

Tool economy takes a leading place in the system of production maintenance. The modern technical and organizational level of mechanical engineering is determined by the high equipment of its models, stamps, molds, fixtures, cutting, measuring and auxiliary tools and devices, combined into a common set of technological equipment.

Large production associations (enterprises) use hundreds of thousands of different types of tools and other technological equipment. The most important indicators of the enterprise's work directly depend on the degree of its perfection, the timeliness of providing jobs and the size of the tool costs: labor productivity, quality and cost of production, rhythm of production.

The cost of tools in mass production reaches 25-30%, in serial production - 10-15%, in small-batch and unit production - up to 5% of the cost of equipment, and their share in the cost of production is 8-15, 6-8, 1, respectively. , 5-4%.

Taking into account the great importance, as well as the specifics and complexity of organizing the production and acquisition of tools, at machine-building plants, tool management services are created, which are entrusted with the following tasks: determining the needs and planning for providing enterprises with equipment; rationing of tooling consumption and maintenance of its stocks at the required level; providing the company with purchased equipment and organizing its own production of high-performance and efficient equipment; providing jobs with tools, organizing their rational operation and restoration; accounting and analysis of the effectiveness of the use of technological equipment.

During operation, technological equipment is subject to physical and moral deterioration and requires constant maintenance. Equipment operability is restored by repairing it. Moreover, during the repair, not only should the original state of the equipment be restored, but it is also necessary to significantly improve its main technical characteristics through modernization.

The essence of the repair is to preserve and restore high-quality equipment performance by replacing or restoring worn parts and adjusting mechanisms.

The main task of the repair facilities is to ensure uninterrupted operation of equipment when minimal costs for repair service. This task is solved by the rational organization of routine maintenance of equipment during its operation in order to prevent progressive wear and tear and accidents, timely scheduled preventive maintenance of equipment, modernization of obsolete equipment, and improve the organizational and technical level of repair facilities.

The power industry of an industrial enterprise is a complex set of production processes, transformation, distribution and use of all types of energy resources. The energy sector ensures the production of various types of energy and energy carriers at this enterprise, carries out installation, operation and repair of energy equipment in production shops and divisions of the enterprise. The largest share in energy consumption is electric energy (more than 30% of all energy consumed). The power supply of enterprises is carried out mainly from regional power systems and less often from their own power plants. Heat carriers - steam and hot water - come mainly from the heating networks of territorial power systems. At enterprises, to obtain carriers of thermal energy, so-called secondary energy resources are widely used - the heat of waste gases from heating furnaces for heating water; the use of hot water and steam obtained during water and evaporative cooling for heating, as well as waste steam from forging and stamping equipment.

The enterprises also use solid, liquid and gaseous fuels, depending on the technology of production of products.

Reliability and uninterrupted power supply are important factors determining a properly organized power supply system and the level of technical operation. Power outages lead to production disruptions and economic damage. The process of production, distribution and consumption of energy is a single energy process in which all elements are interconnected. The structure and volume of the energy supply of the enterprise depend on the type of product, technological process, production capacity and links with the territorial energy sector.

Uninterrupted, well-organized work of the transport facilities of enterprises plays an important role in the high-performance functioning of the main production. According to the territorial basis of service, the transport of the enterprise is divided into external and internal. External transport is intended for the delivery of goods to the enterprise and the removal of finished products and waste from it. Internal (in-plant) transport is designed for the transportation of goods between workshops and warehouses.

The transport sector consists of vehicles (automobiles, trailers, locomotives, diesel locomotives, wagons, electric cars, tractors, etc.) and general-purpose devices (garages, depots, repair shops, rail and trackless tracks). Transportation of goods, loading and unloading and forwarding operations are the main functions of the transport industry. The organization of in-plant transport and its work have a direct impact on the course of the production process and the cost of production. Production depends on the work of transport. The duration of the production cycle is directly affected by the time of transport operations. The costs of maintaining transport and storage facilities and transportation of goods to some enterprises amount to 25-30% of the total indirect costs in the cost of production. In this regard, the main task of this economy is the uninterrupted transportation of goods with the full use of vehicles and the minimum cost of transport operations. This is achieved through the correct organization of the transport economy, clear planning of its work, a reasonable choice of vehicles, an increase in the level of mechanization of loading and unloading operations, and the introduction of effective forms of management.

Warehousing is an integral part of every enterprise. Its task is to ensure the safety of stocks of raw materials and material resources, finished products. She plays an important role in the movement of material values. Almost the entire amount of raw materials and materials, fuel, tools, equipment and spare parts for it, overalls, other products, as well as manufactured products, semi-finished products, production waste passes through the warehouses of the enterprise. Warehouse management is a connecting link between the logistics service and production units, between workshops, as well as divisions of the enterprise.

A significant part of material values \u200b\u200bneeds storage and transportation in containers. A container is a product in which raw materials, semi-finished products or finished products are placed, ensuring their qualitative and quantitative preservation during transportation from the place of their procurement or production to the place of storage or consumption. The purpose of the container is to protect the cargo from damage due to mechanical influences (shock, shock), pollution and environmental influences (temperature, pressure, light, precipitation, etc.), losses during storage and transportation; reduce the time of loading and unloading, improve the general culture of production and create convenience in handling cargo. Containers and means of packaging are needed mainly for shipped products. Their importance is growing with the development of new forms of trade, increased requirements of buyers for goods, etc.

The composition and organization of the container economy depend on the type of products of the enterprise, the consumer's requirements for its packaging, packaging and containers, as well as on cooperation with enterprises - suppliers of containers and packaging materials.

The main tasks of accounting, cost control and calculating the cost of auxiliary production are:

formation of timely, complete and reliable information on the actual costs of auxiliary production at enterprises of various forms of ownership and management;

justified calculation of the actual cost of production of auxiliary industries, correct compilation of accounting estimates of the cost of goods, work, services of auxiliary production;

correct distribution of the costs of auxiliary production to consumers;

identification of reserves for reducing the costs of auxiliary production, prevention of unproductive costs and losses.

Thus, the main task of auxiliary production is to ensure the normal functioning (without interruptions and stops) of the main production and all areas of the enterprise.

2. Documenting and accounting of costs of auxiliary production

Information on the costs of auxiliary production is summarized on the active synthetic account 23 "Auxiliary production". His debit collects all costs directly related to the release of products, the performance of work and the provision of services, as well as the costs of managing and maintaining auxiliary production, and losses from marriage, and on the loan - the amount of the actual cost of the completed production of products, work performed and services provided ...

If necessary indirect costsassociated with the management and maintenance of auxiliary production, can be preliminarily collected on accounts 25 "General production costs" and 26 "General business expenses", and then debited to account 23 "Auxiliary production". In addition, losses from rejects can be recorded on account 28 "Rejects in production" and written off to account 23 "Auxiliary production".

In cooperatives, small and joint organizations, account 23 "Auxiliary production" may not be used, and all costs of auxiliary shops can be taken into account on account 20 "Main production".

The costs incurred in auxiliary production are reflected in the accounting by postings:

Debit account 23 "Auxiliary production",

Credit of account 02 "Depreciation of fixed assets" - for the accrued depreciation on fixed assets of auxiliary production;

Credit of account 05 "Amortization of intangible assets" - for the accrued amortization on intangible assets used in the shops of auxiliary production;

Credit account 10 "Materials" (for the corresponding sub-accounts) - for the amount of inventory items used in the shops of auxiliary production;

Credit account 16 "Deviation in the cost of material assets" - to write off (reversal) deviations for the materials consumed in auxiliary production;

Credit of account 21 "Semi-finished products of own production" - for used semi-finished products of own production in the shops of auxiliary production;

Credit of account 23 "Auxiliary production" - for the amount of services (work) provided by the shops of auxiliary production to each other;

Credit of account 25 "General production costs" - when the share of general production costs of the main production is included in the cost of production of the workshops of auxiliary production;

Credit from account 26 "General business expenses" - when the share of general business expenses is included in the cost of auxiliary production shops;

Credit from account 28 "Defect in production" - to write off losses from defects recorded in the shops of auxiliary production;

Credit of account 43 "Finished goods" - when the finished goods are delivered to the shops of auxiliary production;

Credit from account 50 "Cashier" - to pay in cash for small business expenses of ancillary production;

Credit of account 60 "Settlements with suppliers and contractors" - on the invoices of suppliers and contractors accepted for payment for work, servants performed for the shops of auxiliary production;

Credit of account 68 "Calculations of taxes and fees" - for the amount of taxes accrued to the budget;

Credit of account 69 “Settlements for social insurance and security” - for the amount of contributions to the Social Security Fund;

Credit of account 70 "Payments with personnel for labor remuneration" - for accrued wages to employees of auxiliary production;

Credit of account 71 "Settlements with accountable persons" - for expenses related to business trips of employees of auxiliary production shops;

Credit account 76 "Settlements with different debtors and creditors" - for the cost of work (services) performed by research institutes, design and technological and transport organizations; for the amount of accrued insurance premiums ar property and personal insurance; contributions to extrabudgetary funds in auxiliary industries;

Credit account 94 "Shortages and losses from damage to valuables" - when writing off to the costs of auxiliary production of shortages and losses from damage to valuables within the norms of natural loss;

Credit account 97 "Prepaid expenses" - to write off part of the prepaid expenses related to the reporting period included in the costs of auxiliary production.

To account for the costs of ancillary production, use sheet 12 "Worksheet cost accounting sheet". In simple auxiliary productions, statements No. 12 are opened for each farm: electric shop, boiler house, water pump, compressor station, motor depot, etc. If the energy workshop generates or distributes several types of energy, for example, a heat power workshop - steam, hot water, oxygen, etc., the costs are taken into account in statement 12 for the workshop as a whole, and in addition to it, cards are opened analytical accounting for each type of energy. There is no work in progress. In the industries under consideration, a simple (process-by-process) method of accounting for costs and calculating the cost of production is used.

In complex auxiliary productions, statements 12 are kept, as a rule, for the shop (farm) as a whole and are supplemented with cards for analytical accounting of costs for orders for the manufacture of tools, containers, spare parts for the repair and maintenance of fixed assets. Direct costs are accounted for directly on account 23 "Auxiliary production", and indirect costs can be preliminarily collected on accounts 25/1 "Expenses for the maintenance and operation of machinery and equipment" and 25/2 "General production costs".

After distribution, they are debited to account 23 "Auxiliary production" and are included in the cost of the corresponding orders. If there is a work in progress, even the costs and the calculation of the cost of production are organized by show. Orders are opened for the release of single tooling or for groups of homogeneous tools and fixtures, for objects of non-standard equipment being manufactured or fixed assets being repaired, for a series of spare parts, etc.

Along with one-off, there are also permanent orders for routine repairs and maintenance of equipment, stocking of tools, etc. The costs of standing orders are fully written off at the end of the month to the accounts of the consumer shops without calculating the cost of services.

The main primary documents for accounting for the output of auxiliary production and the provision of services to workshops and other consumer units - invoices for the delivery of tools, devices, models, molds, spare parts, packaging; acts of acceptance and delivery of non-standard equipment, acts of acceptance and delivery of overhauled, modernized and reconstructed facilities; waybills of cars, work sheets of forklift trucks, electric cars, etc.

Thus, the accounting of the costs of auxiliary production is kept on account 23 "Auxiliary production" in statement 12 by shops and in the context of individual items and types of products. The monthly totals of these statements are transferred to journal order 10.

3. Calculation of the cost of production of auxiliary industries. The procedure for allocating the costs of auxiliary production to consumers

Planning, accounting and calculation of the cost of production are carried out according to the nomenclature of cost items established by line ministries and departments, depending on the characteristics of the relevant industry. The most common are the following articles:

materials minus returnable waste;

workers' wages with social security contributions;

equipment maintenance and operation costs;

general production costs;

general expenses (for products and services on the side).

The objects of calculation in auxiliary production are the types of their products, works and services, for which the cost is calculated. It is advisable to use as calculation units: a piece or 100 pieces of tooling, spare parts, containers of the corresponding name and size, an object of non-standard, overhauled or modernized equipment, 1000 kWh of electricity, joule of heat energy, 1000 m3 of compressed air and gas, ton reconditioned lubricants and other auxiliary materials, one service point of ventilation units or low-current communication, ton, ton-kilometer or machine-hour of operation of vehicles, a set of washed or repaired overalls, standard-hour or 1000 rubles. for equipment maintenance, tool sharpening, etc.

It is advisable to supplement natural calculation units with qualitative characteristics of tools and equipment (power, productivity, operational readiness, etc.).

In simple auxiliary industries, due to the absence of work in progress, the costs and production costs are equal. The cost of a calculation unit is determined by dividing the costs accounted for in statement 12 or analytical accounting cards for the corresponding type of product by the amount of energy produced or distributed, transportation or other work performed, i.e., as already noted, a simple (process-based) calculation method is used.

In complex auxiliary production, when calculating the cost of orders and all products, carry-overs of work in progress are taken into account. If several units of products were manufactured for one order, the unit cost is calculated by dividing costs (taking into account changes in work in progress) by the number of products (volume of work). In cases where several types of products were produced on order, the costs between each of them are usually distributed in proportion to the planned (standard) cost.

At the end of the month, the costs accounted for on account 23 “Auxiliary production” are distributed among consumers. Moreover, in complex auxiliary production, the remains of the work in progress are preliminary estimated. The order of their assessment is the same as in the main production, but there are some simplifications. In particular, direct costs in work in progress are allowed to be calculated according to consolidated standards, to distribute costs for the maintenance and operation of machinery and equipment, as well as general production costs - in proportion wages production workers. Products and work delivered on partially completed orders are valued at the planned cost, and the actual cost is determined after the entire order has been completed.

The costs related to the delivered products, works and services are allocated to consumers in accordance with the completed orders or in proportion to the amount of products released (services provided). Moreover, it is necessary to take into account such a feature of auxiliary industries as the mutual consumption of products and services by each other. For example, the energy department supplies energy to the rest of the auxiliary shops, and itself uses the services of the transport department when transporting fuel and materials, repair shops for the repair of buildings, structures and equipment, etc. Therefore, when calculating the costs to be distributed, i.e. the actual cost of production of the corresponding auxiliary production, the cost of counter (accepted and rendered) services should be taken into account, which, to simplify accounting, are usually estimated at the planned cost.

The calculations are summarized in the table "Distribution of services of auxiliary production" or the corresponding machine chart.

When distributing services (works, products) of ancillary industries, postings are drawn up:

Credit account 23 "Auxiliary production";

The debit of account 58 "Financial investments" - when providing as investments to other organizations in the ownership of parts, assemblies, other products, works, services, unfinished auxiliary production for the acquisition of long-term and short-term stock values;

The debit of account 07 "Equipment for installation" - for services rendered by auxiliary industries for the delivery of equipment requiring installation;

The debit of account 08 "Investments in non-current assets" - for the cost of work and services rendered by the shops of auxiliary production for the needs of capital construction;

The debit of account 10 "Materials" (according to the corresponding sub-accounts) (15) - for the produced commodity-material values \u200b\u200bfor in-plant consumption;

The debit of account 20 "Main production" - to write off the services of auxiliary production at the costs of main production;

The debit of account 21 "Semi-finished products of own production" - for the cost of semi-finished products manufactured by the shops of auxiliary production;

The debit of account 23 "Auxiliary production" - for the value of received mutual (counter) services from other shops of auxiliary production;

The debit of account 25 "General production costs" - for the services of auxiliary shops, attributed to general production expenses;

The debit of account 26 "General expenses" - for the services of auxiliary shops, referred to general expenses;

The debit of account 28 "Defect in production" - for the amount of detected defects in tool and repair industries;

The debit of account 29 "Service industries and farms" - to write off the services of auxiliary industries for the costs of service industries and farms;

The debit of account 97 "Deferred expenses" - for the value of orders completed and handed over by the shops of auxiliary production for work and services related to the development of new organizations, industries, shops and units (start-up costs), preparation and development of the release of new types of products and technological processes, not intended for serial and mass production;

The debit of account 43 "Finished goods" - for the cost of finished goods produced by the shops of auxiliary production and delivered to the warehouse;

The debit of account 44 "Sales costs" - for the cost of loading and unloading and transport operations related to the sale of products;

Debit of account 45 "Goods shipped" (90) - for the actual production cost works, services, energy, water and other energy carriers performed and supplied to their service industries and farms, capital construction, if the latter are allocated to an independent balance, as well as to business entities on a contractual basis;

The debit of account 91 "Operating income and expenses" - for the cost of work, services of repair and other auxiliary workshops for the liquidation and sale of fixed assets;

The debit of account 76 "Settlements with different debtors and creditors" - for the cost at the current rates transport servicesprovided by the transport industry for the employees of their organization; to write off losses of work in progress for products discontinued at the initiative of the customer, who admitted it voluntarily or on the basis of a decision of the economic court;

Account debit 92 " Non-operating income and expenses ”- for the costs of canceled orders initiated by the organization for reasons beyond its control; uncompensated losses from natural disasters, including the costs associated with the prevention or elimination of the consequences of natural disasters, as well as losses as a result of fires, accidents, and other emergency events caused by extreme conditions; additional costs for orders completed in previous years; production costs that did not produce products;

The debit of account 94 "Shortages and losses from damage to valuables" - for the value of identified shortages of work in progress in auxiliary shops;

In organizations where instrumental, repair and other auxiliary services function as part of the main workshops, it is not necessary to keep account 23 "Auxiliary production".

Let us consider the distribution of the costs of auxiliary production using an example:

Example 1. One of the workshops of the auxiliary production of LLC Sugar Plant No. 1 produces steam.

This steam is needed to process raw sugar. Steam is also used for the needs of the plant management building, housing and communal services facilities and the auxiliary production workshop, which produces spare parts. In addition, LLC "Sugar Plant No. 1" sells steam to other organizations.

In the 1st quarter of 2011, the steam generation workshop had the following expenses:

payment for water intake - 70 800 rubles. (including VAT - RUB 10,800);

the cost of consumed gas for heating - 177,000 rubles. (including VAT - RUB 27,000);

the cost of consumables for the general needs of the shop - 7080 rubles. (including VAT - 1080 rubles);

salary for shop workers - 60,000 rubles;

deductions to social funds - 18,000 rubles;

depreciation of equipment - 48,000 rubles.

It turns out that in the first quarter the costs of the workshop for the production of steam were:

800 RUB - 10 800 rubles. + 177,000 rubles. - 27,000 rubles. + 7080 rub. - 1080 rubles. + 60,000 rubles. + 18000 rub. + 48,000 rubles. \u003d RUB 342,000

The costs of the auxiliary production shop are distributed among the departments in proportion to the volume of steam consumed as follows:

main production workshop - 55 percent;

workshop of auxiliary production for the production of spare parts - 10 percent;

plant management - 10 percent;

objects of housing and communal services - 15 percent;

other organizations - 10 percent.

Consequently, the costs of the auxiliary production workshop are written off to:

main production shop - 188,100 rubles. (342,000 rubles x 0.55);

workshop of auxiliary production for the production of spare parts - 34,200 rubles. (342,000 rubles x 0.1);

factory management - 34,200 rubles. (342,000 rubles x 0.1);

housing and communal services - 51,300 rubles. (342,000 rubles x 0.15);

other organizations - 34,200 rubles. (342,000 rubles x 0.1).

According to its accounting policy, Sugar Plant No. 1, LLC writes off general business expenses for the products sold in the reporting period. Such expenses of the plant in the first quarter of 2011 amounted to 750,000 rubles. Of these, 144 800 rubles. falls on steam that was sold to other firms.

The following entries were made in the accounting records of Sugar Plant No. 1 for the I quarter of 2007:

Debit 10 Credit 60

RUB 6000 - capitalized materials for the economic needs of the boiler house;

Debit 19 Credit 60

1080 RUB - reflects the amount of VAT on purchased materials;

RUB 150,000 - Reflected expenses for the purchase of gas;

Debit 19 Credit 60

RUB 27,000 - the amount of VAT on purchased gas is reflected;

Debit 23 subaccount "Steam production" Credit 60

RUB 60,000 - reflects the cost of water intake;

Debit 19 Credit 60

RUB 10 800 - the amount of VAT on expenses for water intake is reflected;

Debit 23 subaccount "Steam production" Credit 10

RUB 6000 - materials written off to household needs workshops;

Debit 23 subaccount "Steam production" Credit 70

RUB 60,000 - accrued wages for the shop workers;

Debit 23 subaccount "Steam production" Credit 69

RUB 18,000 - deductions to social funds have been accrued;

Debit 23 subaccount "Steam production" Credit 02

RUB 48,000 - depreciation is charged on fixed assets;

Debit 20 Credit 23 subaccount "Steam production"

188 100 rub. - written off the share of the shop's expenses attributable to the main production;

Debit 23 subaccount "Production of spare parts" Credit 23 subaccount "Production of steam"

RUB 34,200 - written off the share of the costs of the workshop attributable to the workshop for the production of spare parts;

Debit 26 Credit 23 subaccount "Steam production"

RUB 34,200 - written off the share of the shop's expenses attributable to the plant management;

Debit 29 subaccount "Housing and communal services" Credit 23 subaccount "Steam production"

RUB 51 300 - written off the share of the costs of the shop, attributable to the maintenance of housing and communal services;

Debit 90 subaccount "Cost of sales" Credit 23 subaccount "Steam production"

RUB 34,200 - written off the share of the costs of the workshop attributable to steam sold to the side;

Debit 91 subaccount "Cost of sale of a pair" Credit 26

144 800 rub. - the share of general operating expenses attributable to the sale of steam to the side was written off;

Debit 91 subaccount "Cost of sales of the main production" Credit 26

RUB 605,200 (750,000 - 144,800) - the share of general business expenses attributable to sold products of the main production was written off.

4. Computerization of accounting of costs of auxiliary production

The use of computers, which are relatively easy to operate, makes it possible to create automated workstations (AWS) for an accountant. Automation of the accounting process allows ensuring high accuracy of accounting data, efficiency of accounting. Many laborious operations for systematization, coding, generalization and verification of information are disappearing. There is no need to print most of the accounting registers on paper, since only those of them are printed that are necessary for current work and filling out reporting forms. The possibilities of interactive communication with computers, obtaining the necessary data upon request, are widely used. The work of an accountant is becoming more intellectual and creative.

The automated form of accounting is based on the methodological, informational, technical, organizational and legal unity of information processing in various areas, including obtaining a balance sheet and reporting forms.

Currently, enterprises are given the right to choose the form of accounting themselves. Based on the recommended forms, they can develop their own original forms, observing the general methodological principles:

documentary reflection of business transactions, incl. on machine media having legal force of primary documents;

standardization and unification of documents;

cost estimation of accounting objects;

economic grouping of accounting objects based on a system of accounts;

ensuring the relationship between accounting indicators based on double entry and balance sheet generalization;

formation and drawing up of reporting forms according to a unified methodology for all structural divisions of the enterprise and the enterprise as a whole;

the possibility of developing the system.

Computerization of accounting allows:

to carry out the processing of primary documents directly at the accountant's workplace using a personal computer;

promptly receive, process and accumulate information coming from peripheral equipment;

solve problems in a query mode, control the results of calculations, carry out repeated counting;

document a number of business transactions and get days off accounting registers - machine charts directly at the accountant's workplace;

improve the organization of accounting, reduce its labor intensity, improve efficiency and quality.

Therefore, computerization of accounting should be widespread at all enterprises of the Russian Federation.

ancillary cost price accounting

Conclusion

Auxiliary production is included in the production structure of almost every large enterprise; the number of such industries, the types of products produced by them, and the organization of accounting for their costs depends on the industry and production characteristics of the enterprise. At the same time, auxiliary production is distinguished, typical for most enterprises: energy, transport, repair and mechanical.

A feature of accounting for the costs of auxiliary production is its economic essence, determined by the ratio to the products of the main production. Auxiliary production costs are indirect or overhead in relation to the products of the main production, even if they are direct in relation to the products of the workshop in which they are produced.

For example, depreciation of a vehicle warehouse or an electric heating line is a direct cost for the motor vehicle and energy shops, respectively, but in relation to the products of the main production, they must be distributed in accordance with a certain distribution base.

Expenses are allocated by cost items, which include: wages with deductions for social needs, basic materials (energy, semi-finished products, spare parts), maintenance of fixed assets, work and services, and other costs.

Distribution of costs in the energy and motor transport shops is carried out monthly, according to the first - in proportion to the amount of consumed energy and its planned cost, according to the second - in proportion to the volume of work in ton-kilometers and their planned cost .. adjusted to actual.

The costs of the workshop for the production of spare parts are written off monthly in the planned amount to the cost of work performed in proportion to the direct wages of workers - a more traditional method used also for the distribution of general production and general business workers. At the end of the year, the planned size of shop floor costs is adjusted to actual costs, with some of them attributed to work in progress.

List of sources used

1. Bakaev A.S. Some issues of accounting // Accounting - No. 3, 2011. -6-8 p.

2. Bezrukikh P.S. Accounting. - M .: Accounting, 2010. -532p.

Financial accounting: Textbook for universities / Ed. prof. Yu.A. Babaeva. - M .: University textbook, 2010 .-- 525 p.

Financial accounting: a textbook for students studying in the specialties: "Finance and credit", "Accounting. accounting, analysis and audit "/ PI. Kamyshanov, A.P. Kamyshanov. - 5th ed., Rev. and add. - M.: Omega-L, 2008 .-- 589 p.

Vrublevsky N.D. Cost accounting in production: Textbook. M .: INFRA-M, 2007 .-- 118s.

Glushkov I.E. Accounting in modern enterprises: Textbook. M .: Delo, 2008. - 608s.

Iokhin V.Ya. Economics. - M .: Jurist, 2011. - 568 p.

Kozhinov V.Ya. Accounting: Textbook. M .: Exam, 2012, - 120s.

Ladutko N.I. Accounting in industry: textbook. allowance / N.I. Ladutko. - Minsk: Book House, 2012 .-- 688 p.

Papkovskaya P.Ya. Accounting: textbook. manual / ed. P. Ya. Papkovskaya. - 3rd ed., Rev. - Minsk, 2012. - 236 p.

Chart of accounts of accounting (Approved by order of the Ministry of Finance of Russia No. 94n dated 31.10.2000), M., 2007. - 265 p.

Strazheva N.S. Accounting: study guide. manual / N.S. Strazheva, A.V. Strazhev. - 10th ed., Rev. and add. - Minsk: Book House, 2010 .-- 432 p.

Tutoring

Need help exploring a topic?

Our experts will advise or provide tutoring services on topics of interest to you.

Send a request with the indication of the topic right now to find out about the possibility of obtaining a consultation.