Requirements for the building part

1.5. When designing general commodity warehouses, the following should be envisaged:

Possibility of their blocking and subsequent expansion, and in a warehouse of more than 5000 m 2 the possibility of construction and commissioning of capacities in queues;

Comprehensive solution of mechanization issues and organization of storage facilities along the entire route of goods movement from supplier to consumer

Widespread introduction of the system of supply of goods to stores using packaging equipment, containers;

Comprehensive mechanization of loading and unloading, transport and storage operations (PRTSR), mechanization and automation of warehouse management systems, mechanization and automation of engineering equipment technological processes;

Application of progressive methods of storage of food and non-food products, ensuring the improvement of the use of warehouse space and volume and preservation of the quality of goods;

Measures to protect material assets.

1.6. In warehouses for storing food and non-food products (universal), the ratio of areas should be taken:

for non-food products (with a shelf life of 50 days) - 75 percent

for food products (with a shelf life of perishable goods - 15 days, uncooled - 30 days) - 25 percent

The area of \u200b\u200brefrigerated chambers or perishable goods should be taken in the amount of 20 percent of the warehouse area intended for storing food products, including:

for refrigerated goods - 80 percent

for frozen goods - 20 percent

The indicated ratios of areas and storage times in days for individual groups of goods are specified in the design assignment and project, depending on specific conditions.

1.7. When designing refrigerated chambers that are part of warehouses for food products, one should be guided by the norms of technological design and technical and economic indicators of refrigerators.

1.8. Storage periods in days for individual groups of goods are indicated in the design assignment.

1.9. The organization of the flow chart in general commodity warehouses by groups of operations should be provided taking into account the recommended Appendix 1.

1.10. The list of goods stored in general commodity warehouses and their average volumetric weight are indicated in Appendix 2.

The overall dimensions of the racks for long and bulky goods should be taken taking into account the overall dimensions of the goods.

3.5. To store the finished dress in a suspended form, mechanized hangers, bracket-carriages, special rack pallets with rods should be used.

3.6. The types of pallets and container equipment used for the transportation and storage of goods, depending on the characteristics of the goods, are given in Appendix 12.

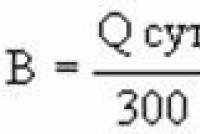

3.7. In food warehouses, scales with a weighing limit of up to 2000 kg should be provided and installed on the route of cargo (on platforms, on expeditions, in sections). The number of scales depends on the daily cargo turnover and is determined by the formula:

, pcs., (3.1)

, pcs., (3.1)

where: B - the number of scales, pcs;

Q days - value of daily cargo turnover, conventional pallet;

300 - the number of pallets per one scale;

2 is a constant.

3.8. The auxiliary equipment includes: scrapping tables, equipment for mechanical repair and carpentry workshops, charging equipment, equipment for cleaning premises, paramannequins, etc. (The dimensions of the scrapping tables are given in Appendix 13). The list and brief characteristics of the equipment for cleaning floors are given in Appendix 14.

3.9. The need for lifting and transport equipment is determined according to the standards for the technical equipment of general warehouses and is specified by the calculation given in the mandatory Appendix 23.

3.10. The use of mechanisms powered by internal combustion engines inside the premises of general warehouses is not allowed.

3.11. When choosing the means of mechanization, it is necessary to provide for the joint use of floor battery transport and rack machines in order to increase the utilization rate of both the area and the volume of storage facilities.

Rack-serving machines operating in automatic mode are advisable to be used for goods with a high turnover, with racks longer than 50 meters.

With a shorter racking length, support stacker cranes and floor-standing battery power tools should be used.

3.12. When shipping products from general warehouses in packaged form, provide, with appropriate justification, the use of bag-forming, packaging and strapping machines and installations.

3.13. Mechanization level ( U m ), which is an indicator of the technical equipment of general commodity warehouses, should be determined by the ratio of the volume of work performed by a mechanized method ( Q fur ), to the total amount of work ( Q fur + Q ruch )

, % (3.2)

, % (3.2)

The level of mechanization in general warehouses must be at least 55%.

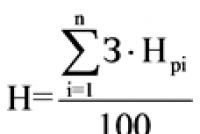

The main production workers of the warehouse include: loaders, machine operators, storekeepers. Their number should be determined by the formula:

, people, (4.1)

, people, (4.1)

where: H vr - the norm of time for 1 conventional pallet or 1 ton of processed cargo for a specific type of work performed by one employee, man-h;

H vr - determined by ENViV. Due to the fact that in ENViV H vr are indicated for 1 ton of cargo, to account for the work performed with cargo formed on pallets, the time rate should be divided by the correction factor β

, (4.2)

where: q - the average mass of cargo on one pallet for the corresponding group of goods, t (see clause 2.8).

When several correction factors are applied to a time rate, the final time rate for a particular work option is determined by multiplying the basic time rate by the product of the applied coefficients.

q - the volume of processed goods per shift at each operation of the technological process, conv. pallets or t ( Q post + Q send );

K 1 - coefficient of unaccounted and additional technological operations with cargo

K 1 =1,1

K 2 - the rate of absence from work due to illness; holidays, etc.

K 2 =1,14

F - duration of the shift, h.

An example of calculating the number of warehouse personnel employed in loading and unloading and transport and storage operations of a warehouse for non-food products, see Appendix 20.

4.1. Auxiliary workers include workers employed in maintenance operations for equipment of all power plants, employees of charging stations, mechanical repair and carpentry workshops. When determining the number of these workers, one should be guided by Appendices 17, 21.

4.2. The number of managers, engineers and technicians, employees and other specialists should be determined depending on the warehouse turnover.

____________________

* When designing the OP ACS, one should be guided by "Typical design solutions for the complex of technical means of reference points for collection, primary processing and transmission of information with reference to the designs of buildings of general commodity warehouses", developed by the PTI "Beltorgsistema" and approved by the UPiKS of the USSR Ministry of Trade, 1985

5.1. OP ACS is intended for collecting, primary processing and transmission of information about the economic activities of the warehouse for further processing to the branch or territorial information and computing center (ITC).

5.2. The construction of a complex of technical means (CTS) should be based on modern mass-produced equipment. The main types of technical means are presented in Appendix 15.

5.3. When choosing technical means and determining their number, it is necessary to take into account the amount of information to be processed on a specific type of machine, the production rates of operators or the speed of computers, as well as the possibility of ensuring the joint operation of computing systems (VC) with a network of remote video terminal devices (VTU) and providing them with the necessary the number of automated workstations (AWS) of specialists of the main divisions of the general warehouse.

The number of VTUs for equipping AWPs (AWP-management, AWP-product expert, AWP - storekeeper, etc.) should be determined depending on the structure of the general warehouse.

5.4. The area of \u200b\u200bthe OP ACS is determined depending on the installed equipment and the number of workplaces.

OP ACS should be located in a complex with administrative premises.

VTU, operated as part of AWPs, should be located directly at the workplaces of the relevant specialists of general commodity warehouses.

5.5. The number of operators of desktop technical equipment (TS) in one-shift operation should be taken according to the number of vehicles. The number of personnel serving the VC should be taken depending on the type of VC, work shifts, the volume and nature of the tasks being solved.

5.6. Maintenance and repair of the CTS should be carried out by the mechanics of the ITC, which carries out further information processing, or the mechanics of specialized organizations.

______________________

* Organized when the need for maintenance and repair of warehouse equipment is declared.

The standards for the frequency, duration and labor intensity of repairs for electric forklifts and crane equipment are given in the Regulation on scheduled preventive repair and maintenance of lifting and transport and technological equipment of power and heat power plants of bases and enterprises of the USSR State Committee for Supply. For the rest of the warehouse equipment Standards for the frequency, duration and labor intensity of repairs are given in the Regulations on the system of maintenance and repair of trade and technological equipment - order of the USSR Ministry of Trade of October 3, 1980 N 264.

6.1. The repair shops of the general warehouse include: a mechanical workshop with a welding section and a carpentry workshop. The mechanical workshop performs maintenance, routine (small), medium repairs of equipment and warehouse inventory.

The carpentry workshop carries out routine repairs of wooden elements of buildings and structures, as well as routine repairs of pallets, wooden containers and equipment, container equipment.

6.2. The calculation of the required amount of the main equipment of a mechanical repair workshop is made based on the annual labor intensity of repair work for machine tool work for the entire amount of equipment.

Number of main machines ( n ) should be determined by the formula:

, pcs., (6.1)

, pcs., (6.1)

where: TΣN st - total finished labor intensity of repair work for machine tool work for the entire amount of equipment, h;

F d - actual (calculated) annual fund of machine operation time, h;

K zag - machine load factor

K zag =0,6-0,8.

6.3. In addition to the calculated number of main machines, auxiliary equipment should be provided, which includes: machines - table-drilling, sharpening and grinding, circular saw, hydraulic press, welding transformer, drive shears, etc.

The approximate composition of the equipment of mechanical and carpentry shops, depending on the storage area, see Appendix 16.

6.4. The number of production workers in a mechanical repair shop is determined by the formula:

, (6.2)

, (6.2)

where: TΣN w - total annual labor intensity of repair plumbing work for the entire amount of equipment, h;

K - coefficient of multi-station service and combination of professions

K =1,05-1,1;

F dr - the actual annual fund of the worker's time, hours (see table 6).

6.5. The calculation of the number and equipment of a carpentry workshop should be made based on the volume of repair work in accordance with the Design Standards for woodworking workshops of machine-building plants, approved by the USSR Ministry of Automotive Industry (Giproavtoprom).

The number of production workers in the carpentry workshop ( R ) is determined by the formula:

Chel, (6.3)

where Q " - the volume of work of the carpentry workshop, thousand rubles in year

q ’ - output per worker, thousand rubles

The approximate area and staffing of repair shops are given in Appendix 17.

6.6. Annual funds of time and design modes of operation of equipment and worker are given in Table 6

Table 6

|

Working duration, weeks, h |

Number of shifts |

Duration of shifts, h |

Number of working days per year |

Length of main vacation |

Actual annual fund of time, h |

|

|

Equipment |

worker |

|||||

|

2070 |

1860 |

|||||

|

4140 |

1860 |

|||||

7.1. The territory of the general commodity warehouse must be fenced. Entry and exit of vehicles should be designed through the checkpoint.

7.2. The width of the cargo yard at the vehicle platforms of the warehouse building should be taken depending on the type of vehicles and the intensity of cargo turnover, taking into account the circular, dead-end or mixed traffic patterns.

The width of the lane for the movement of a car in one direction should be taken equal to four and a half meters.

The width of the cargo yard from the vehicle platform to the side stone must be at least 24 meters.

If the car platforms of two warehouse buildings are located on both sides of the cargo yard, one against the other, the width of the yard between them must be at least 32 meters. The specified dimensions are subject to specification in the projects.

7.3. Column spacing for single-storey and multi-storey warehouses should be taken taking into account the requirements of SNiP II-104-76 "Warehouse buildings and structures of general purpose".

7.4. Interfloor ceilings of multi-storey warehouses should be calculated on the actual useful standard load in accordance with the requirements of SNiP II-6-74 "Loads and Impacts".

7.5. The height of one-storey warehouses (from the floor to the bottom of the supporting structures of the coverings on the support) must be a multiple of 0.6 meters, but not less than 6 meters.

The height of multi-storey warehouses (the distance from the floor of a given floor to the floor of the overlying floor) should, as a rule, be 6 meters.

The height of the expedition premises should be taken, as a rule, in one-storey warehouses - 4.2 meters to the bottom of the supporting structures; in multi-storey buildings - based on the data of a technical and economic calculation, based on the ratio of the areas occupied on the first floor by the expedition and storage facilities.

7.6. When developing master plans and space-planning solutions for general commodity warehouses, it is necessary to provide for the possibility of their future expansion in accordance with the design assignment.

7.7. The dimensions of the gates in warehouses should be set depending on the dimensions of the goods being moved and the vehicles to be replaced and taken according to Table 7.width

height

Electric pallet truck with railway container

3200

3200

Ministry of Trade of the USSR

DEPARTMENTAL STANDARDS FOR TECHNOLOGICAL DESIGN OF PUBLIC WAREHOUSES

Date of introduction 1986-01-01

INTRODUCED by the State Union Design Institute (Giprotorg) of the USSR Ministry of Trade

APPROVED by order of the USSR Ministry of Trade of November 15, 1985 No. 254 in agreement with the USSR State Construction Committee and the State Committee for Science and Technology on September 3, 1985 No. 45-500

REPLACE VNTP 02-84 / Ministry of Trade of the USSR

1. General Provisions

1.1. The present departmental norms for the technological design of general commodity warehouses * / USSR Ministry of Trade apply to the design of newly built and reconstructed warehouses intended for storing food and non-food consumer goods of the USSR Ministry of Trade's nomenclature **.

* In the following text, abbreviated: "norms".

** Engineers from Giprotorg participated in the development: I.I. Afanasyeva, L.M. Borminskaya, V.G. Kupriyanov, V.M. Fatuev, V.M. Stankovsky, E.N. Smolevitsky, M.I. Friedman, R.B. Feigin, N.S. Edelstein, N.D. Epstein.

1.2. The norms do not apply to the design of distribution refrigerators, vegetable stores, potato stores, fruit stores, warehouses for building materials and explosives.

1.3. The design and construction of general commodity warehouses should be carried out in accordance with the duly approved scheme for the development and placement of general commodity warehouses, the requirements of the relevant chapters of SNiP and other all-Union and departmental regulatory documents.

1.4. The design and construction of general commodity warehouses should be carried out in accordance with the nomenclature of types of general commodity warehouses, approved by the order of the USSR Ministry of Trade of October 27, 1976, No. 198, given in table. one.

Table 1

1.5. When designing general commodity warehouses, the following should be provided:

the possibility of their blocking and subsequent expansion, and in a warehouse of more than 5000 m2 the possibility of construction and commissioning of capacities in queues;

comprehensive solution of mechanization issues and organization of storage facilities along the entire route of movement of goods from supplier to consumer;

widespread introduction of a system for supplying goods to stores using packaging equipment, containers;

comprehensive mechanization of loading and unloading, transport and storage operations (PRTSR), mechanization and automation of warehouse management systems, mechanization and automation of technological processes of engineering equipment;

the use of progressive methods of storage of food and non-food products, ensuring the improvement of the use of storage space and volume and the preservation of the quality of goods;

measures for the protection of material values.

1.6. In warehouses for storing food and non-food products (universal), the ratio of areas should be taken:

for non-food products (with a shelf life of 50 days) - 75 percent

for food products (with a shelf life

perishable goods - 15 days, uncooled - 30 days) - 25 percent

The area of \u200b\u200brefrigerated chambers or perishable goods should be taken in the amount of 20 percent of the warehouse area intended for storing food products, including:

for refrigerated goods - 80 percent

for frozen goods - 20 percent

The specified ratios of areas and storage times in days for individual groups of goods are specified in the design assignment and project, depending on specific conditions.

1.7. When designing refrigerated chambers that are part of warehouses for food products, one should be guided by the norms of technological design and technical and economic indicators of refrigerators.

1.8. Storage periods in days for individual groups of goods are indicated in the design assignment.

1.9. The organization of the flow chart in general warehouses by groups of operations should be provided taking into account the recommended Appendix 1.

1.10. The list of goods stored in general warehouses and their average volumetric weight are indicated in Appendix 2.

2. Technological part and mechanization of warehouse operations *

* Means of mechanization for the operations of the technological process are indicated in the recommended Appendix 1.

Terminology adopted in these standards:

Trade and Warehouse Complex (TSC) - placement on a common site of one or more buildings of warehouses for storing food and non-food products, a distribution refrigerator, vegetable stores, potato stores and fruit stores with processing workshops, factories for the production of semi-finished products, culinary and confectionery products, as well as necessary ancillary facilities and engineering facilities.

Wholesale base - the main economic link of the wholesale trade, carrying out wholesale purchase and sale (supply) of goods and provision of services to enterprises and organizations of retail trade.

General goods warehouse - a structural unit of wholesale or retail trade, the purpose of which is the storage and processing of goods that do not require special conditions.

2.1. The general warehouse includes the following premises: the main production purpose (warehouse building), auxiliary purpose and auxiliary. For their composition and purpose, see table. 2.

table 2

|

Composition of premises |

Purpose of premises |

|

The main industrial purpose (warehouse building) |

|

|

Warehouse premises (sections) |

Acceptance of goods by quantity and quality, sorting, sorting, storage, picking according to orders of trading organizations, pre-sale preparation |

|

Cooled chambers |

Storage of goods requiring special temperature and humidity conditions |

|

Filling workshop (including departments of raw materials and finished products) |

Packing goods into consumer packaging |

|

Premises for pre-sale preparation |

Preparation of goods for sale (ironing garments, etc.) |

|

Expeditions |

Reception and shipment of goods |

|

Section for storing conflicting batches of goods |

Temporary storage of goods in the event of a discrepancy between the actual availability of goods and the data specified in the accompanying documents |

|

Auxiliary purpose |

|

|

Repair shops (mechanical with a welding section and carpentry) |

Maintenance, routine repair of equipment, inventory, packaging and routine repair of buildings and structures |

|

Chargers |

Battery charging for floor vehicles |

|

Garage of the day of handling equipment |

Parking lot for trucks |

|

Cold store engine room |

Refrigeration equipment placement |

|

Railway landing stages, closed auto platforms and boxes |

Unloading of incoming and loading of dispatched goods |

|

Material warehouse |

Storage of materials, equipment and inventory |

|

Container warehouse |

Storage of empty and returnable containers |

|

Pantry for packaging waste (paper, cardboard, plastic film, etc.) |

Storage and pressing of packaging waste |

|

Pantry of household equipment |

Storage of household equipment and cleaning machines |

|

Washing of industrial containers and equipment |

|

|

Ventilation chambers |

Placement of ventilation units |

|

Heat point |

Placement of the input unit and water heaters |

|

Switchboard, transformer substation |

Placement of transformers and switchboards |

|

Radio center |

Placement of broadcasting devices |

|

Automatic telephone exchange (PBX) |

Placement of PBX equipment |

|

Corridors, lobbies, stairwells, elevator shafts, vestibules, unloading platforms in front of elevators |

|

|

Fire-guard room |

Accommodation of fire and burglar alarms and security personnel |

|

Auxiliary premises |

|

|

Service and utility rooms, pass bureaus |

Accommodation of administrative and managerial personnel and sanitary devices |

|

Food points, health center |

Canteens, buffet, dining rooms, medical staff |

|

Sample rooms |

Exhibition of samples of goods in stock |

|

Strongpoint of the automated control system (OP ACS) |

Placement of the complex of technical means of the OP ACS |

2.2. The warehouse building, as a rule, should be combined with auxiliary and utility rooms in compliance with the requirements of SNiP, PUE and other regulatory documents.

2.3. The general warehouse for non-food products does not include the engine room and refrigerators.

2.4. With appropriate justification on the territory of warehouses for food products, the construction of truck scales may be provided.

2.5. When placing a warehouse on the territory of an operating base, the list of structures and premises required for construction is indicated in the design assignment.

2.6. When drawing up a design assignment, the possibility of cooperation between auxiliary and auxiliary services should be taken into account.

2.7. The total area of \u200b\u200bthe general commodity warehouse is subdivided into warehouse, utility, auxiliary.

The total area is defined as the sum of the areas of the premises of all above-ground floors, including technical, basement and basement, measured within the inner surfaces of the outer walls (or the axes of the outer columns where there are no outer walls), galleries, tunnels, all tiers of shelves, platforms, mezzanines, ramps and passages to other buildings. Areas for servicing crane runways, cranes and conveyors are not included in the total area.

The warehouse area is determined by the sum of the areas of the premises indicated in table. 2.

The utility area is determined by the sum of the areas of the premises indicated in table. 2.

The auxiliary area is determined by the sum of the areas of the premises indicated in table. 2.

The approximate ratio of warehouse, utility and auxiliary areas to the total area of \u200b\u200bthe general warehouse is given in table. 3.

Table 3

|

The ratio of areas as a percentage of the total area |

|||

|

warehouse |

utility room |

auxiliary |

|

|

Warehouse for food products |

|||

|

Warehouse for non-food products |

|||

|

Warehouse for food and non-food products (universal) |

|||

|

Notes: 1. The indicators are given without taking into account the areas of open platforms and container sites, as well as additional detached buildings and engineering facilities. 2. The table shows indicators for general warehouses. For united wholesale bases, the specified ratio is specified by the project, depending on the number of wholesale organizations. |

2.8. The main parameters characterizing the capacity of a general warehouse are: storage area (m2), storage volume (m3), capacity - capacity (m3, conventional pallet, wagon).

With a warehouse height of up to 6 meters, the warehouse capacity is determined by the warehouse area; at a higher height - by indicators of storage volume and capacity or by the area reduced to a height of 6 meters by multiplying the storage area by the reduction factor K:

Kprev \u003d,

where: Нfact is the actual height of the room (to the bottom of the supporting structures), m.

The storage volume is determined by multiplying the storage area by the height of the premises from the floor to the bottom of the supporting structures of the floor (covering).

The cargo volume is determined by the product of the cargo area (see clause 2.9) by the storage height (from the floor to the top point of the cargo).

ATTENTION! THIS DOCUMENT IS NOT AN OFFICIAL VERSION. REFERENCE INFORMATION FOR INFORMATION PURPOSES ONLY.

Ministry of Trade of the USSR

DEPARTMENTAL STANDARDS FOR TECHNOLOGICAL DESIGN

GENERAL WAREHOUSES

Date of introduction

INTRODUCED by the State Union Design Institute (Giprotorg) of the USSR Ministry of Trade

APPROVED by order of the USSR Ministry of Trade of 01.01.01 N 254 \u200b\u200bin agreement with the USSR State Construction Committee and the State Committee for Science and Technology on September 3, 1985 N 45-500

1. General Provisions

Packing goods into consumer packaging

Premises for pre-sale preparation

Preparation of goods for sale (ironing garments, etc.)

Expeditions

Reception and shipment of goods

Section for storing conflicting batches of goods

Temporary storage of goods in the event of a discrepancy between the actual availability of goods and the data specified in the accompanying documents

Auxiliary purpose

Repair shops (mechanical with a welding section and carpentry)

Maintenance, routine repair of equipment, inventory, packaging and routine repair of buildings and structures

Chargers

Railway landing stages, closed auto platforms and boxes

Unloading of incoming and loading of dispatched goods

Material warehouse

Storage of materials, equipment and inventory

Container warehouse

Storage of empty and returnable containers

Pantry for packaging waste (paper, cardboard, plastic film, etc.)

Storage and pressing of packaging waste

Pantry of household equipment

Storage of household equipment and cleaning machines

Washing of industrial containers and equipment

Ventilation chambers

Switchboard, transformer substation

Placement of transformers and switchboards

Radio center

Placement of broadcasting devices

Automatic telephone exchange (PBX)

Placement of PBX equipment

Corridors, lobbies, stairwells, elevator shafts, vestibules, unloading platforms in front of elevators

Accommodation of fire and burglar alarms and security personnel

Auxiliary premises

Service and utility rooms, pass bureaus

Accommodation of administrative and managerial personnel and sanitary devices

Food points, health center

Sample rooms

Exhibition of samples of goods in stock

Placement of the complex of technical means of the OP ACS

2.2. The warehouse building, as a rule, should be combined with auxiliary and utility rooms in compliance with the requirements of SNiP, PUE and other regulatory documents.

2.3. The general warehouse for non-food products does not include the engine room and refrigerators.

2.4. With appropriate justification on the territory of warehouses for food products, the construction of truck scales may be provided.

2.5. When placing a warehouse on the territory of an operating base, the list of structures and premises required for construction is indicated in the design assignment.

2.6. When drawing up a design assignment, the possibility of cooperation between auxiliary and auxiliary services should be taken into account.

2.7. The total area of \u200b\u200bthe general commodity warehouse is subdivided into warehouse, utility, auxiliary.

The total area is defined as the sum of the areas of the premises of all above-ground floors, including technical, basement and basement, measured within the inner surfaces of the outer walls (or the axes of the outer columns where there are no outer walls), galleries, tunnels, all tiers of shelves, platforms, mezzanines, ramps and passages to other buildings. Areas for servicing crane runways, cranes and conveyors are not included in the total area.

The warehouse area is determined by the sum of the areas of the premises indicated in Table 2.

The auxiliary area is determined by the sum of the areas of the premises indicated in Table 2.

The auxiliary area is determined by the sum of the areas of the premises indicated in Table 2.

The approximate ratio of the warehouse, utility and auxiliary areas to the total area of \u200b\u200bthe general warehouse is given in Table 3.

Table 3

|

The ratio of areas as a percentage of the total area |

|||

|

warehouse |

utility room |

auxiliary |

|

|

Warehouse for food products | |||

|

Warehouse for non-food products | |||

|

Warehouse for food and non-food products (universal) | |||

|

Notes: 1. Indicators are given without taking into account the areas of open platforms and container sites, as well as additional detached buildings and engineering facilities. |

|||

|

2. The table shows indicators for general warehouses. For united wholesale bases, the specified ratio is specified by the project, depending on the number of wholesale organizations. |

2.8. The main parameters characterizing the capacity of a general warehouse are: storage area (m), storage volume (m), capacity - capacity (m, conventional pallet, wagon).

With a warehouse height of up to 6 meters, the warehouse capacity is determined by the warehouse area; at a higher height - by indicators of storage volume and capacity or by the area reduced to a height of 6 meters by multiplying the storage area by the reduction factor

![]() ,

,

where: - the actual height of the room (to the bottom of the supporting structures), m.

The storage volume is determined by multiplying the storage area by the height of the premises from the floor to the bottom of the supporting structures of the floor (covering).

The cargo volume is determined by the product of the cargo area (see clause 2.9) by the storage height (from the floor to the top point of the cargo).

The utilization factor of the general warehouse volume is determined by the ratio of the cargo volume to the warehouse volume.

Capacity (capacity) - the volume of goods placed in storage sections, refrigerated chambers, expeditions and sections for storing conflicting parties (m, conventional pallet or wagon).

A pallet of 800x1200 mm with a stacking height of 1050 mm should be taken as a conventional pallet.

The total height of a product package is 1200 m, the volume of goods in a conventional pallet is 1 m. The average weight of one m of food products is 0.5 tons; one m of non-food products - 0.37 tons.

The main type of covered wagon should be a four-axle wagon with a carrying capacity of 62 tons and a capacity of 100 conventional pallets.

A universal container (GOST) for mixed, rail, road and water transportation with dimensions of 2100x1325x2400 mm, volume - 5.3 m, capacity - six conventional pallets, nominal gross weight 2.5 (3) tons should be taken as a conventional container.

2.9. Determination of the areas of the main production purpose (warehouse building).

The warehouse area should be determined by the formula:

where: - area of \u200b\u200bstorage sections, m;

where: - the area required for work on the quantitative and qualitative acceptance of goods, selection and pre-sale preparation;

Cargo area occupied by equipment (racks, pallets, containers) intended for storing goods, m;

where: - capacity of warehouse sections, conv. pallet

The area required to install one pallet, m

when stored in a stack \u003d 1

when stored in racks \u003d 1.2

The number of tiers for stacking pallets with goods in height (for warehouses with a height of 6 meters, an average of 4 tiers are taken).

Passage areas () and () are determined by multiplying the cargo area by the coefficients

a) when storing food products

![]() , m (2.5)

, m (2.5)

b) when storing non-food products

![]() , m (2.6)

, m (2.6)

![]() , m. (2.7)

, m. (2.7)

Expedition area is determined by the formula:

CONV. pallet (2.9)

And - see clause 2.16

When calculating the area of \u200b\u200bthe expedition of warehouses for food products, it should be taken with coefficients 0.2, based on the fact that:

perishable goods go directly to refrigerated chambers, prepared for sale can be on the expedition for no more than two hours;

most of the uncooled food products (sugar, flour, etc.) are accepted and sent bypassing the expedition.

Coefficient taking into account passages and driveways for vehicles, indents from walls and heating devices

The area of \u200b\u200bstorage sections for conflicting parties is part of the area of \u200b\u200bexpeditions and is calculated based on the possibility of storing batches of goods in the amount of 10-15 percent of their daily receipt.

The minimum area of \u200b\u200bthe section should ensure the possibility of storing goods in the volume of one four-axle wagon in the presence of a railway or in the volume of one universal container when they arrive by road.

The area of \u200b\u200bthe filling shops is determined depending on the productivity and equipment. The need to organize packing shops is indicated in the design assignment.

2.10. The width of the aisles between the shelves should be taken according to the technical parameters of the equipment used (see Appendices 9, 10, 11), but not less than 0.8 meters. As a rule, the aisles between the racks should be circular. It is allowed to arrange dead-end passages with the length of racks not exceeding 25 meters. When using hand-operated stacker cranes and floor stackers with swivel forks, the width of the aisle should be taken without taking into account the turning of the mechanism or turning the forks (these operations are performed in the central aisle).

The minimum width of the central passage in two-way traffic is 3 meters. The width is specified in the project, depending on the adopted mechanisms and dimensions of the transported goods, according to the formula:

where: - width of the mechanism or load protruding beyond the dimensions of the mechanism, mm;

The gap between two passing mechanisms, between the mechanism and the rack (stack) (\u003d 100 mm).

The width of the passage in one-way traffic should be determined by the sum of the width of the mechanism (load) and the doubled clearance, but not less than 1.4 meters.

The dimensions of the indentations of goods or equipment intended for storage should be taken:

Notes. 1. It is allowed to install racks or stacks with an indent from the walls and wall columns by 5-10 cm in cases where the indents are not used for evacuating people.

2. The dimensions of the indentations from the heating devices must be increased if required by the storage conditions of the goods.

The distance in the stack between pallets or containers is 5-10 cm.

2.11. The average standards of warehouse area and warehouse volume for storing one conventional pallet are shown in Table 4.

Table 4

|

Unit of measure |

In warehouses for food products |

In warehouses for non-food products |

||||

|

single-storey with a height of 6 m to structures |

many - storeyed with a height of 6 m from floor to floor |

one-story with a height of 6 m to const |

storey with partial high-rise storage |

storeyed with a height of 6 m from floor to floor |

||

|

Warehouse space standard | ||||||

|

Warehouse volume standard | ||||||

|

Notes: 1. Column 5 in parentheses indicates the standard only for the high-rise storage area with a warehouse height of 16.2 m. |

||||||

|

2. The standard of storage volume for multi-storey warehouses is specified by the project depending on the accepted floor structures. |

2.12. The averaged ratios of area elements, taking into account a wide variety of space-planning and technological solutions, adopted storage methods and means of mechanization, as well as the ratio of heated and cooled areas are given in recommended appendices 3 and 4.

The area ratios were drawn up according to standard designs for one-story warehouses with a room height of 6 meters to the bottom of the supporting structures.

2.13. Storage methods and the type of processing equipment should be determined depending on the type, volume and packaging of the goods.

Storage of goods with a large range and packaging dimensions multiples of a standard pallet (1200x800 mm) should be provided on flat pallets or with mesh fencing, installed in the shelving cells.

The storage of goods of the same type (sugar, flour, etc.), arriving in large volumes and making it possible to create a stable stack, should be provided on flat pallets in a stack.

If the packaging of such goods does not allow a stable stack to be created, stacked rack pallets or flat pallets placed on shelving shelves should be used.

Storage of the finished dress should be provided, as a rule, on mechanized hangers, bracket carriages or special rack pallets with rods that can be installed on the shelves of universal racks or stacked one on top of the other.

2.14. Determination of the areas of utility rooms.

The area of \u200b\u200bthe material warehouse, storage room for packaging waste is determined by the design assignment. If this area is not indicated in the assignment, it should be taken in accordance with Table 5

Table 5

|

Warehouse area of \u200b\u200bthe general warehouse, m |

Material warehouse area, m |

Pantry area for waste, packaging, m |

The area of \u200b\u200bthe container warehouse should be taken at the rate of 25 m per wagon of daily receipt of goods, but not less than 50 m.

VNTP 02-85

Ministry of Trade of the USSR

GOVERNMENTAL STANDARDS

TECHNOLOGICAL DESIGN

GENERAL WAREHOUSES

Date of introduction 1986-01-01

INTRODUCED by the State Union Design Institute (Giprotorg) of the USSR Ministry of Trade

APPROVED by order of the USSR Ministry of Trade of November 15, 1985 No. 254 in agreement with the USSR State Construction Committee and the State Committee for Science and Technology on September 3, 1985 No. 45-500

REPLACE VNTP 02-84 / Ministry of Trade of the USSR

1. General Provisions

|

Warehouse area (m 2) |

|||||

|

For food products |

2500 |

5000 |

10000 |

15000 |

25000 |

|

For non-food products |

2500 |

5000 |

10000 |

15000 |

25000 |

|

For food and non-food products (universal) |

2500 |

5000 |

10000 |

15000 |

|

|

Note ... In some cases (for small towns and villages), it is allowed to design and build general commodity warehouses with an area of \u200b\u200bless than 2500 m2, taking into account the requirements of these standards. |

|||||

Terminology adopted in these standards:

Trade and warehouse complex (TSK) - placement on a common site of one or several buildings of warehouses for storing food and non-food products, a distribution refrigerator, vegetable stores, potato stores and fruit stores with processing workshops, a factory for the production of semi-finished products, culinary and confectionery products, as well as the necessary ancillary premises and engineering facilities ...

Wholesale base - the main economic link of the wholesale trade, carrying out the wholesale purchase and sale (supply) of goods and the provision of services to enterprises and retail organizations.

General warehouse - a structural unit of wholesale or retail trade, the purpose of which is the storage and processing of goods that do not require special conditions.

|

Purpose of premises |

|

|

The main industrial purpose (warehouse building) |

|

|

Warehouses (sections) |

Acceptance of goods by quantity and quality, sorting, sorting, storage, picking by orders of trading organizations, pre-sale preparation |

|

Cooled chambers |

Storage of goods requiring special temperature and humidity conditions |

|

Filling workshop (including departments of raw materials and finished products) |

Packing goods into consumer packaging |

|

Premises for pre-sale preparation |

Preparation of goods for sale (ironing garments, etc.) |

|

Expeditions |

Reception and shipment of goods |

|

Section for storing conflicting batches of goods |

Temporary storage of goods in the event of a discrepancy between the actual availability of goods and the data specified in the accompanying documents |

|

Auxiliary purpose |

|

|

Repair shops (mechanical with a welding section and carpentry) |

Maintenance, routine repair of equipment, inventory, packaging and routine repair of buildings and structures |

|

Chargers |

Battery charging for floor vehicles |

|

Garage of the day of handling equipment |

Parking lot for trucks |

|

Cold store engine room |

Refrigeration equipment placement |

|

Railway landing stages, closed auto platforms and boxes |

Unloading of incoming and loading of dispatched goods |

|

Material warehouse |

Storage of materials, equipment and inventory |

|

Container warehouse |

Storage of empty and returnable containers |

|

Pantry for packaging waste (paper, cardboard, plastic film, etc.) |

Storage and pressing of packaging waste |

|

Pantry of household equipment |

Storage of household equipment and cleaning machines |

|

Washing room |

Washing of industrial containers and equipment |

|

Ventilation chambers |

Placement of ventilation units |

|

Heat point |

Placement of the input unit and water heaters |

|

Switchboard, transformer substation |

Placement of transformers and switchboards |

|

Radio center |

Placement of broadcasting devices |

|

Automatic telephone exchange (PBX) |

Placement of PBX equipment |

|

Corridors, lobbies, staircases, elevator shafts, vestibules, unloading areas in front of elevators |

|

|

Fire-guard room |

Accommodation of fire and burglar alarms and security personnel |

|

Auxiliary premises |

|

|

Service and utility rooms, pass bureaus |

Accommodation of administrative and managerial personnel and sanitary appliances |

|

Food points, health center |

Canteens, buffet, dining rooms, medical staff |

|

Sample rooms |

Exhibition of samples of goods in stock |

|

Strongpoint of the automated control system (OP ACS) |

Placement of the complex of technical means of the OP ACS |

The auxiliary area is determined by the sum of the areas of the premises indicated in table. ...

The auxiliary area is determined by the sum of the areas of the premises indicated in table. ...

The approximate ratio of warehouse, utility and auxiliary areas to the total area of \u200b\u200bthe general warehouse is given in table. ...

|

The ratio of areas as a percentage of the total area |

|||

|

warehouse |

utility room |

auxiliary |

|

|

Warehouse for food products |

63 - 66 |

28 - 24 |

9 - 10 |

|

Warehouse for non-food products |

67 - 70 |

25 - 20 |

8 - 10 |

|

Warehouse for food and non-food products (universal) |

64 - 67 |

27 - 23 |

9 - 10 |

|

2. The table shows indicators for general warehouses. For united wholesale bases, the specified ratio is specified by the project, depending on the number of wholesale organizations. |

|||

where: S section - area of \u200b\u200bstorage sections, m 2;

where: S out - the area required for carrying out work on the quantitative and qualitative receipt of goods, selection and pre-sale preparation;

S gr - cargo area occupied by equipment (racks, pallets, containers) intended for storing goods, m 2;

where: E - capacity of warehouse sections, conv. pallet;

n - the area required to install one pallet, m 2;

when stored in a stackn \u003d 1;

when stored in racksn \u003d 1.2;

q - the number of tiers of stacking pallets with goods in height (for warehouses with a height of 6 meters, an average of 4 tiers are taken).

Passage areas (S pr) and (S out ) are determined by multiplying the cargo area by the coefficients

a) when storing food products

b) when storing non-food products

Expedition area is determined by the formula:

Q post and Q send - see p.

Q days when calculating the area of \u200b\u200bthe expedition of warehouses for food products should be taken with coefficients of 0.2, based on the fact that:

perishable goods go directly to refrigerated chambers, prepared for sale, can be on the expedition for no more than two hours;

most of the uncooled food products (sugar, flour, etc.) are accepted and sent, bypassing the expedition.

K is a coefficient that takes into account walkways and driveways for vehicles, indents from walls and heating devices

K \u003d 2.3.

The area of \u200b\u200bstorage sections for conflicting parties is included in the area of \u200b\u200bexpeditions and is calculated based on the possibility of storing batches of goods in the amount of 10-15 percent of their daily receipt.

The minimum area of \u200b\u200bthe section should ensure the possibility of storing goods in the volume of one four-axle wagon in the presence of a railway or in the volume of one universal container when they arrive by road.

Packaging workshops areaS face determined depending on performance and equipment. The need to organize packing shops is indicated in the design assignment.

|

unit of measurement |

In warehouses for food products |

In warehouses for non-food products |

||||

|

single-storey with a height of 6 m to structures |

single-storey with partial high-rise storage |

multi-storey with a height of 6 m from floor to floor |

||||

|

Warehouse space standard |

m 2 |

0,85 |

0,45 (0,30) |

1,35 |

||

|

Warehouse volume standard |

m 3 |

5,0 - 5,6 |

4,5 (4,1) |

6,4 - 7,2 |

||

|

Notes : 1. Column 5 in brackets indicates the standard only for the high-rise storage area with a warehouse height of 16.2 m. |

||||||

|

2. The standard of storage volume for multi-storey warehouses is specified by the project depending on the accepted floor structures. |

||||||

|

Material warehouse area, m 2 |

Pantry area for waste, packaging, m 2 |

|

|

2500 |

||

|

5000 |

||

|

10000 |

||

|

15000 |

||

|

25000 |

The area of \u200b\u200bthe container warehouse should be taken at the rate of 25 m 2 per wagon of daily receipt of goods, but not less than 50 m 2.

The area of \u200b\u200bthe premises of the engine room of refrigerated chambers is determined in accordance with the Temporary norms for technological design and technical and economic indicators of refrigerators (VNTP-03 -76).

When designing charging storage batteries for floor vehicles, be guided by the Guidelines for the Design of Charging Stations for Traction and Starter Storage Batteries of Tyazhpromelektroproekt, approved by the UPO of the USSR Ministry of Internal Affairs and the State Energy Supervision Authority of the USSR Ministry of Energy.

The areas of the premises for engineering support, that is, a switchboard, a transformer substation, a heating point, a radio center, ATS, ventilation chambers, etc., should be arranged depending on the equipment installed in them, taking into account the requirements of the current regulatory documents.

The areas of service and utility rooms, food points, health centers, etc. are determined taking into account SNiP II-92-76 "Auxiliary buildings and premises of industrial enterprises", depending on the number of workers in the warehouse and groups of production processes.

When located in the warehouse sections of the workplaces of the warehouse manager and storekeepers, it is allowed to fence them with glazed partitions to a height of 1.8 meters.

The area for one workplace should be taken in the amount of 3-4 m 2.

where: E - storage capacity (excluding the capacity of expeditions), conventional pallet;

K 1, K 2 - the coefficients of unevenness, respectively, the receipt and dispatch: K 1 \u003d 1.3; K 2 \u003d 1.2;

D \u003d 365 - the number of working days of the warehouse to receive goods arriving by rail;

D \u003d 305 - the number of working days of the warehouse for the receipt and dispatch of goods arriving and dispatched by road;

K ob - the coefficient of turnover

where: n - the number of incoming or outgoing wagons per day;

l 1 - length of a four-axle car, m;

K - coefficient of unevenness of receipt or dispatch (K 1 or K 2), see p.;

l 2 - addition to the length of the dead end for the stop device and the inaccuracy of the installation of cars, m.

For railway landing stagel 2 \u003d 10 m, for open railway platforml 2 \u003d 4 m.

This formula takes into account one supply of wagons per day. The number of feeds is set by calculation in the project.

The length of the loading and unloading front of the automobile platform is determined by the formula:

t - time spent by the machine under loading or unloading;

The time spent by vehicles under loading and unloading is taken in accordance with the Directory of Uniform Tariffs for Freight and Passenger Transportation and Road Transport Services. Second revised edition. ("Transport", 1975).

3. Equipment of general goods warehouses

The level of mechanization in general warehouses must be at least 55%.

4. Determination of the number of warehouse workers

The main production workers of the warehouse include: loaders, machine operators, storekeepers. Their number should be determined by the formula:

where: q is the average mass of cargo on one pallet for the corresponding group of goods, t (see p.).

When several correction factors are applied to a time rate, the final time rate for a particular work option is determined by multiplying the basic time rate by the product of the applied coefficients.

Q ¢ - the volume of processed goods per shift at each operation of the technological process, conv. pallets or t (Q post + Q send);

К 1 - coefficient of unaccounted and additional technological operations with cargo

K 1 \u003d 1.1

K 2 - coefficient of absenteeism due to illness; holidays, etc.

K 2 \u003d 1.14

F is the duration of the shift, h.

An example of calculating the number of warehouse personnel employed in loading and unloading and transport and storage operations of a warehouse for non-food products, see the appendix.

where: T S N st - total finished labor intensity of repair work for machine tool work for the entire amount of equipment, h;

F D - actual (calculated) annual fund of machine operation time, h;

K zag - load factor of machines

K zag \u003d 0.6 - 0.8.

where: T S N cl - total annual labor intensity of repair plumbing work for the entire amount of equipment, h;

K - coefficient of multi-station service and combination of professions

K \u003d 1.05 - 1.1;

F DR - the actual annual fund of the worker's time, h (see table).

where Q ² - volume of work of the carpentry workshop, thousand rubles in year

q ¢ - output per worker, thousand rubles

The approximate areas and staffs of repair shops are given in the appendix.

|

Number of shifts |

Duration of shifts, h |

Number of working days per year |

Length of main vacation |

Actual annual fund of time, h |

||

|

equipment |

worker |

|||||

|

2070 |

1860 |

|||||

|

4140 |

1860 |

|||||

7. Requirements for the building part

|

Minimum door dimensions in the clear, mm |

||

|

width |

height |

|

|

Electric pallet truck with railway container |

3200 |

3200 |

|

Electric forklift with a fork lift of 4.5 m (double frame) |

2100 |

3200 |

|

Electric forklift with a fork lift of 4.5 m (three-frame) |

2100 |

2400 |

|

Electric forklift with fork lift 2.8 m |

2100 |

2400 |

|

Self-propelled and manual trolleys with container equipment or piece cargo |

2100 |

2400 |

|

Unit of change |

Water consumption rates (l) |

Temperature, ° С |

Water quality |

|

|

Washing of lifting vehicles (electric forklifts, electric cars, etc.) |

one car |

40 - 50 |

drinking water |

|

|

Washing containers, inventory, equipment |

m 2 surface |

60 - 65 |

drinking water |

|

|

Washing floors |

m 2 surface |

40 - 50 |

drinking water |

|

Estimated indoor air temperature (for the cold season), ° С |

Air exchange rate per hour |

||

|

inflow |

hood |

||

|

1. Warehouses for non-food items |

|||

|

2. Warehouses for food products |

|||

|

3. Expeditions |

2 (in the absence of an air-thermal curtain) |

||

|

4. Workshops for packing granulated sugar and cereals |

Balance |

2 (and additionally local suction from technological equipment) |

|

|

5. Premises for pre-sale preparation |

|||

|

6. Sections of storage of conflicting goods |

|||

|

7. Material warehouse |

|||

|

8. Pantry containers |

|||

|

9. Repair shops |

by calculation |

||

|

10. Railway landing stage |

|||

|

11. Closed boxes for cars |

by calculation |

||

|

12. Sample rooms |

|||

|

Note ... The design air temperature and the rate of air exchange for office and utility rooms should be taken in accordance with SNiP "Auxiliary buildings and premises of industrial enterprises". |

|||

where: G m - the weight of the incoming goods in kg / h, taken according to the technological task;

C is the specific heat capacity of these goods in kcal / kg deg, C \u003d 0.35;

B - coefficient taking into account the intensity of heat absorption for the first hour B \u003d 0.5

for the second hour B \u003d 0.3

for the third hour, B \u003d 0.2;

t in - indoor air temperature;

t m - temperature of imported goods for non-food products

t m \u003d t n + 10 ° С,

for food products

t m \u003d t n + 20 ° C;

t n - design temperature of the outside air (parameters B SNiP "Heating, ventilation and air conditioning").

|

Illumination (in suites) |

||

|

with fluorescent lamps |

with incandescent lamps |

|

|

Warehouses of fabrics and haberdashery goods |

100 |

50 |

|

Warehouses of other non-food products |

75 |

20 |

|

Furniture warehouses with grading |

||

|

Food warehouses |

75 |

20 |

|

Packing shops |

||

|

Expeditions |

||

|

Braker places |

||

|

Closed landing stages |

||

|

Platforms |

||

|

Notes : 1. Illumination is indicated for warehouses without natural light and with constant presence of people. Illumination for warehouses with natural light is reduced by one step 2. Columns 2 and 3 in the numerator show the illumination of non-automated warehouses, in the denominator - for automated ones. 3. To ensure the illumination indicated in the table above the braker's workplaces, in addition to the general one, an additional local lighting device is required. |

||

|

Isolated area no more than (m 2) |

Room capacity taking into account the filling factor of the container with goods, no more (m 3) |

|

|

Flammable liquids |

||

|

Hot liquids |

||

|

Aerosol products |

|