Wholesale of lumber

The forest industry has always been considered a profitable area. Extraction, sale and processing of wood can bring very serious money. However, for beginners, entering this market promises a lot of problems. Sad statistics show that up to 90% of entrepreneurs who have opened one or another "forest" business close in the first year of work ...

Business Basics

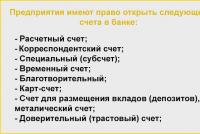

The best option with limited capital is the wholesale trade in lumber (timber). Nevertheless, the costs of starting a business, in comparison with the opening of production, are much less here and you won’t have to risk much. In some cases, you can do without start-up capital at all, if you do not take into account the costs of registering an LLC and opening a current account. The scheme of work looks classic: 1. you find a client who needs lumber 2. you take a 100% prepayment from him 3. you pay for the order from the manufacturer from the received money 4. you keep the extra charge. But there are some nuances here.

The most popular lumber: edged board (spruce / pine of the first and second grade), timber, lining and slab. The cost of the board depends on the type of wood and the scope of delivery. These are the main indicators. But the price depends on several factors. So, timber can be planed and unplaned, solid, profiled solid and glued. Solid timber is considered the most expensive, and glued - the cheapest.

In the case of edged boards, the type of wood plays an important role. Different breeds have different characteristics in terms of moisture resistance, strength, resistance to drying, and so on. The most common species are conifers (pine, spruce, larch). Very cheap lumber is obtained from pine and spruce. Boards made of oak, cedar and larch are of the greatest value.

The best clients are industrial production and construction companies. Construction companies often take boards, timber, slabs for the construction of wooden houses, baths and cottages. Among the clients are many manufacturers of furniture and pallets. Small industries buy edged boards for the manufacture of windows, floors, stairs, pallets.

How much can you earn

The minimum prices for edged boards of the first grade start from 5000 rubles. per cubic meter. At the same time, if you carefully search the Internet, you can be sure that the price for the same product (for example, edged board of the 1st grade) can differ significantly. In places rich in forests, prices will be lower due to high competition. But in the capital region and closer to the south, first-class boards ask for 6,000 rubles per cubic meter. and more. The difference of 20 - 30% is the wholesaler's income. From 100 cubic meters it turns out about 100,000 rubles.

A separate issue is the delivery of lumber. Often, in order to make good money, you have to look for suppliers thousands of kilometers away. This is where logistics plays a big role.

The best option is delivery by wagons. Up to 70 cubic meters of birch timber are included in a gondola car. The transportation service costs from 100 rubles. from the cube (depending on the distance of delivery). Prices can be obtained from the company that provides the rolling stock.

Transportation by heavy vehicles becomes relevant for small volumes and transportation over short distances, when delivery times begin to be decided. But there is one problem: the board, especially wet, is quite heavy. So, 1 cubic meter. raw pine weighs at least 0.75 tons. Therefore, a standard truck will fit no more than 27 cubic meters, although the truck will fit up to 80 cubic meters. Solution: carry only a dry board.

Organizational moments

It is better to look for suppliers in regions rich in forest. For example, in the Kirov region. There are a lot of manufacturers, and the price level is much lower. “Be sure to study GOSTs and standards,” absolutely all industry professionals repeat. This will avoid a lot of unpleasant situations with buyers. A classic example: a client ordered a board of the first grade, and received a second or third grade (a product with completely different board quality indicators). As a result, the client is not satisfied, demands a price reduction or even a refund. And these are losses, and, above all, for the supplier. If you buy a board from an unfamiliar manufacturer, then you should personally be present at the shipment of the first batch of goods. In this case, you will see with your own eyes what is being loaded into the truck.

“There is almost no money in sawing up. It is most profitable to carry dried edged and raw unedged boards,” say participants in the professional forum forums.wood.ru. And in general, it is best to start a business with sales. This is a more correct and reliable way to start. If you have found a client, then it will not take long to calculate the logistics and approximate profit.

You can study the market for demand in many ways, even without having the status of a registered businessman. You can advertise on Avito by adding your margin to the average market wholesale price. If there are calls, then you simply write down the client's contacts and in the same way begin to look for a supplier with the most reasonable prices and terms of cooperation. And only after a sufficient number of pre-orders have been received, planning, business registration, extensive advertising and so on begins.

“For the future, it is good to have a base for warehousing and a small office at the warehouse at hand,” say market participants. This greatly expands business opportunities. Lumber can be sold by self-delivery, invite customers to the office to conclude contracts. Here the client can inspect the samples, as well as make sure that you are not a one-day company, but have your own stocks of products.

"Myths of the lumber dealer"

1. Goods only after 100% prepayment. No one will get you lucky lumber with a delay. Sawmills are small industries, and they will not take risks by shipping goods on credit, they will not look for transport for you. Therefore, you find the car yourself, come to pick up the board, pay for the loading and leave. Everyone is happy.

2. Price - quality. You should not try to buy a first-class board very cheaply. Understand that a quality board of the 1st grade cannot cost less than 5000 rubles. per cubic meter. If you are offered by phone to buy a high-quality board for nothing, then this is another reason to doubt the honesty of the manufacturer. Nobody will work at a loss. It's just that you can get not the first grade, but a board from the first to the third grade. Yes, anything you want can be shipped, even ordinary firewood.

3. Production time. As a rule, they are always underestimated. Do not think that if the manufacturer promises to produce 35 cubes of board or timber for you in a week, then that is exactly what will happen. The usual tape frame according to the passport has a capacity of 5 cubic meters of lumber per shift. In reality, workers produce no more than 4 cubes. And this is not 1 grade, but from 1 to 3 grades. In fact, in a week, if you work seven days a week (which is unlikely in our villages), you will be made no more than 28 cubes.

4. Roads. When sending transport to a remote village, get ready for the fact that it can literally get stuck there. Roads in the villages exist only as guides, and no one will lay asphalt for you there.

5. Documents. Almost all owners of sawmills are ordinary individual entrepreneurs and almost all of them work on the simplified tax system. So you can not even try to look for a manufacturer that works with VAT. Many of them don't even do bookkeeping. The only paper they will issue you will be a receipt for the removal of lumber.