Plan for the production of work sample. This page contains samples of documents that are necessary when conducting high-altitude work. These are acts, outfits, tolerances and PPRs. List of project decisions and measures to ensure fire safety in the period

Here you can familiarize yourself with the examples of work projects.

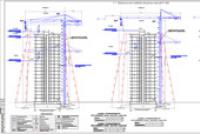

PPRK (Draft production of works by cranes)

The installation and safe operation of three tower cranes during the construction of a series of monolithic residential buildings is considered. Due to the constraintful conditions of the cranes, they work with the restriction of the service zone.

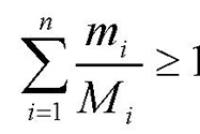

Stationary tower cranes Jaso J110N and Jaso J140N brands are built by the designs of a 19-storey building from 0.000 to ONM. +63.000. Cranes are mounted on the foundation supports with a plane mark -2.200, with anchor mounting tower.

The maximum lifting load with taps on 10 tons 2.5-15m is 5 tons, on 10-40m flying - 2.5 tons.

Tower cranes are used at all stages of construction underground and overhead part of the building, namely:

- for unloading from motor vehicles and storage of materials and products as they arrive at the construction site

- for feeding packs of reinforcement, arms and formwork, as well as for supplying concrete in Badjah when erecting monolithic structures

- to feed on the mounting horizon of small-piece materials and mortar

- for feeding and removing construction equipment, equipment, consumables, etc.

Project volume: anguing note A4 - 35 sheets, drawings A1 - 5 sheets

This example of the PPR on the excavation of a pit under the protection of a tongue fence. Excavation is made in 3 stages.

- Stage 1. Work at 135.50 ÷ 134.60 is performed by the Hitachi ZX 200 excavator with a bucket capacity of 0.8 m3 (the maximum digging radius is 9.75m, the maximum depth of digging is 6.49 m) equipped with a "reverse shovel" with loading of the soil into the automotive loading. With a lag behind 4 meters from the work of the Hitachi ZX 200 excavator, the installation of a strapping belt is made (1 N45 B2 2). Installation is carried out by the car crane on a separately developed PPR.

- Stage 2. Work at a mark of 132.50 is performed by the Hitachi ZX 200 excavator. At this level, it is developed to the design depth of 127.84 ÷ 127.84 m, by developing and moving the soil into the automotive industry. With a lag of 4 meters from the operation of the ZX 200 excavator, a spacer design is performed, consisting of a strapping belt (2 2 of the N45 B2 2), squeezing from pipes 426x10mm in the axes 1 ÷ 10 and pods, as well as from pipes 630x12mm in the axes 11 ÷ 16. Installation is carried out by the car crane on a separately developed PPR.

- Stage 3. Excavation of the slopes are carried out by developing and moving the soil by the Bobcat S330 excavator into the Hitachi ZX 225 granting zone. The grab produces the designed ground to the surface and load it into the automotive industry. From the pit, the Bobcat S330 excavator is issued at the end of the work by the auto crane on a separately developed PPR.

At the last stage, the recess of the soil of Berm under the mounted bounces of the tongue fencing of the pit with the use of the mini-scab.

Project volume: anguishing note A4 - 28 sheets, drawings A1 - 5 sheets

Project of production of works on the construction of water pipes by the method of the Barocharech

Laying the water supply in a case, built by the closed method of the bubbling penetration. Also the excavation of the working kittlenery of the rectangular shape and the receiving round mine is considered.

Works on the laying of pipes from the bubbling penetration are carried out in several stages:

- 1st stage. Pilot strip, consisting of a rod and a pilot head, the length of the interval from the starting to the receiving pit. The exact direction of the track is provided by the pilot head position control system, the position information is displayed on the monitor screen suspended in the starting mine.

- 2nd stage. Plushing the casing steel pipes and an expander mounted in the starting pit on the last pillow rod within the length of the entire interval between the pit. Purchase pipes from the starting pit with the simultaneous extraction of squeezed casing steel pipes in the receiving pit. The crushing pipes with the drilling head in the head part of the pipe columns serving for the development of the soil into the slaughter, transporting the soil from the hammer to the baud in the starting pit is made by a screw conveyor.

- 3rd stage. Purchase of working pipes with a diameter, smaller or equal to the diameter of casing, with simultaneous melting of casing and the links of the screw conveyor in the receiving pit and their disassembly. When the diameter of the working pipes is less than the diameter of the casing, the construction gap (space), which formed between the working pipeline and the inner surface of the production, is subject to filling with the tamponium solution.

The volume of the project: anguishing note A4 - 25 sheets, drawings A1 - 4 sheets

PPR on the device of a tongue fence and burbilling piles

An example of the PPR on the device of a tongue fencing of the pit in the secure zone of the power supply (power lines). Performing boronobiling piles: Forging the wells by screws, installation of arm-carcasque piles drilling rig, filling the pile by concrete mixture by bottom-up.

Drilling of Burbinal Piles Ø620 mm is made by drilling rig based on "Hitachi"

The drilling of each well should begin after the instrumental check of the marks of the planned surface of the Earth and the position of the circuit axes on the site.

Pialy concreting is made by supplying a concrete mix in a well through hollow augers.

As the concrete is applied to the well, it is lifted and disassembling the screws of the screws, and the level of concrete in the well should be higher than the reservoir nose at least 1 m. The distance between the wellness of the wells and the lower end of the auger at the beginning of concreting should not exceed 30 cm.

Project volume: anguishing A4 note - 20 sheets, drawings A1 - 6 sheets

Project manufacturing work on the installation of forests

Example of the PPR on the installation of forests by the facade of the building under construction

Forests The racking clamps are a spatial frame-long-tier system mounted from tubular elements: racks, cross-line, longitudinal and diagonal bonds, which are connected with the help of nodal connections - clamps.

The fastening of forests to the wall is performed using anchors laid in 14 mm diameter breeded in the walls.

Forests must be attached to the wall of the building under construction. The mount is carried out at least through one tier to attach racks, after two spans for the upper tier and one attachment for every 50 square meters of projection of the forest surface on the facade of the building.

Project volume: anguishing A4 note - 38 sheets, drawings A1 - 4 sheets

Based on what you must have a PPR? List of regulatory documents.

General data (start)

The project's work project was developed for a complete amount of work on the dismantling of crane-beams and crane beams on the Options. 14.40m in the axes "A" - "in" x "2" - "14" of the object: "The building of the shopping and entertainment complex (the completion of the construction of an incomplete construction of the facility) on the street. In Kirov. "

The source data for the development of the PPR was:

Task the customer to develop a project;

Technical Report on the results of technical examination of the main building structures of the building

Design and estimate documentation;

One hundred Nostroy 2.33.52-2011 "Organization of a construction site. New construction";

SNIP 12-01-2004 "Organization of construction production";

Decree of the Government of the Russian Federation of April 25, 2012 No. 390 "Fire Regulations in the Russian Federation"

N123 FZ RF Technical Regulations on Fire Safety Requirements.

SP 4.13130.2013 "Fire protection systems. Restriction of fire distribution at protection objects. Requirements for volume-planning and constructive solutions "

Pue-voluntary 7 "Rules of electrical installation devices";

Snip 12-04-2002 "Labor safety in construction";

SNIP12-03-2001 "Labor safety in construction";

PB 10-382-00. "Rules of device and safe operation of lifting cranes"

Snip P-12-77 "Noise Protection";

SP 2.2.3.1383-03 "Hygienic requirements for the organization of construction production and construction work";

List of designs subject to dismantling

On the designed object in the axes "A" - "in" x "2" - "14" at the mark of 14,400, three crane-beams are subject to a total weight of 5.58t and four "threads" of crane beams, a total length of 528.0 m and weighing 26,506t.

Guidelines for work

Disassembly of structures should perform a specialized construction organization with a license to perform this kind of work.

Disassembly of structures to perform in the sequence, on its construction.

All work on the disassembly of structures is carried out with the help of two trunctable lifting tables with a carrying capacity of 5.0th and the pneumocole crane of the KS-4361 grade with a load capacity of 16t with a length of the boom 10m.

Disassembling suspended crane beam with a loading capacity of 2t before the start of the work of dismantling the crane beams must be performed:

b) In the course of the device, dismantle the crane beams at the mark of 14.400 along the axis "b" in the axes "7" - "9" dismantling the crane-beams in the following technological sequence:

Two three trial lifting tables ZSP 5B with a lifting capacity of 5t, serving as a means of flashing, and as jacks for lowering beams;

Removable support nodes;

General data (end)

With the help of three-skate lifting tables 3P 5B with a loading capacity of 5T, the crane beams are lowered to the mark +8.55, before the start of lowering, two manual lever winches with a carrying capacity of 1.5t are installed on the lower belt of reinforced concrete farms;

With the help of two manual lever, the lifting capacity of 1.5t crane is lifted, lifting tables are displayed, after which the crane beam is installed on two trolleys;

With the help of the electric winch and two transport carts, the crane -bank is fed into the working area of \u200b\u200bthe pneumocole crane K-161.

Crane beams rarely and with a crane are lowered down, in the car body.

Disassembly of crane-beams and their horizontal transportation is performed by the link of installers from six people (see Buildingplane and work schedule)

Disassembly of metal crane beams

Before the production of work on the dismantling of metal crane beams must be performed:

a) perform an opening device in the ceiling at a mark +7,200 in the axes "A / 2" - "b / 2" x "7" - "8/1" (previously designed);

b) In the course of the device, dismantle the crane beams at a mark 14.400 along the axis "b" in the axes "7" - "9".

c) dismantle the crane beams to OTM. 14.400 In the axes "A / 2" - "b / 2" x "7" - "8/1".

Dismantling of crane beams lead in the following technological sequence:

In each of the 12-meter spans, two three-dimensional lifting tables of 3P 5B with a loading capacity of 5t, serving as a means of flashing, and as jacks to lower the beams;

Using the "Bulgarian", autogen or manual arc welding, support nodes are cut;

With the help of three-lifting tables of 3sp 5B with a loading capacity of 5t, it is lowered to the mark +8.55, before the start of lowering, two manual lever winches with a carrying capacity of 1.5t are installed on the lower belt of reinforced concrete farms;

With the help of two manual lever, a lifting capacity of 1.5t subsension beam is raised, the lifting tables are displayed, after which the beam is installed on two trolleys;

With the help of the electric winch and two transport carts, the subordinate beam is messed up into the working area of \u200b\u200bthe pneumocole crane K-161.

The crane beams fall down and with the help of a crane go down, in the car body.

Dismantling of crane beams and their horizontal transportation is carried out by the link of installers from six people (see BuildingPlan and work schedule)

Indications on Safe Working Methods

The adopted organizational and technological disassembly scheme fully ensures safe working conditions working on the construction site, due to:

- Selection of mechanismshiporgrupplapping devices.

- Limitations of cargo transfer zones.

- Selection of safe work methods.

- SELECTING MODING FAMILIES.

Moreover:

In accordance with the current legislation, the obligation to ensure the safe conditions of labor protection at the construction site are assigned to the employer, and it follows:

- In the production of construction and installation work, the requirements of SNiP 12-04-2002 and SNiP 12-03-2001 "Labor Safety in Construction" should be observed.

- Disassembly of structures are made under the direct guidance of an engineering-equipment officer appointed by the order for the organization.

- Workers are allowed to work after briefing at the workplace on the safety of labor, taking into account the features of the disassembly of the building of this design.

- All construction workers should be provided with personal protective equipment.

- When lifting dismantled structural elements, the vertical position of cargo ropes should be provided, universal traverses are used to this end. It is not allowed to pull the valves of squeezed slings and ropes, the rise of the non-fully liberated complicle designs, pulling them off during the rise, move and lower.

- It is forbidden to overlapping the overlap by disassembled elements.

- The fence is provided by the dangerous member of the percentage of 1.2m according to GOST 23407-78, which ensures the closure of access to unauthorized persons.

- The coverage of the work zone of the work of the PZS-35 typelights installed on the designs of an existing building, from the calculation of the illumination of 2 LCs. - PB 10-382-00. "Rules of device and safe operation of lifting cranes"

- Operation of lifting machines is performed according to the "Device Rules and Safe Operation of Lifting Cranes"

- Electrical safety on the construction site to ensure in accordance with the requirements of PUE V.7 "Rules of electrical installations" and GOST 12.1.013-78 "Construction. Electrical safety".

- In order to reduce noise, both on the construction site and beyond. PPR recommends applying electrical and pneumatic tool with low noise characteristics.

- Sanitary and household premises must be equipped in accordance with the hygienic requirements for the device and equipment of premises for workers' and assembly organizations approved by the Ministry of Health, and must meet fire standards.

- At the construction facility should be necessarily aid kits with medicines, stretchers, a set of fixing tires and other means to provide first aid.

- At all areas of work, where it is required by working conditions, equipment, machinery and mechanisms, on roads and other dangerous places, post-visible in the dark day, lit warning and indexing inscriptions and safety signs, posters and safety instructions .

List of project decisions and measures to ensure fire safety during the construction period

When organizing a construction site and maintaining construction and installation work, it is strictly guided by the Decree of the Government of the Russian Federation of April 25, 2012 No. 390 "Rules of fire regime in the Russian Federation". "Technical Regulations on Fire Safety Requirements No. 123 of the Russian Federation", SP 4.13130.2013 "Fire protection systems. Restriction of fire distribution at protection objects. Requirement and planning constructures "and data indications.

- The project provides for an entrance, both to those under construction, temporary and existing buildings and structures. The entrance to the building under construction corresponds to P.8.3 "B" SP 4.13130.2013.

- The entry to the construction site provides for the installation of a shield with a fire protection plan with deposited and auxiliary buildings and structures, entry, entrances, location of water sources, fire extinguishing and communication facilities.

- By the beginning of construction, the construction should be provided with fire water supply (existing facilities) and rebuilding.

Description of solutions for export and disposal of waste

Before the utilization of various elements, materials and waste, they must be sorted and resolved by the issue of their use.

Metal elements: Truck beams - use during the construction of temporary buildings and structures, for low-rise construction and agricultural construction. Male metal rolling is surrendered to enterprises "Commissure".

Metal rental from disassembly of crane beams are exported by transport contractors to specially selected areas.

Guidelines for construction

The construction plan is designed for a period of dismantling crane-beams and crane beams for ONM. 14.400 In the axes "A" - "in" X "2" - "14", the object: "The building of the shopping and entertainment complex (the completion of the construction is not completed by the construction of the facility) on the street. In Kirov"

The construction general plan reflects:

Dismantling of crane beams and crane beams to carry out with the help of two three-time lifting tables of the ZSP5B brand with a lifting capacity of 5t with a lifting height of 1.35-7.2m and a working platform of 1200x4200mm. Loading crane-beams and crane beams with otm. 7.200 In the car body, produce with a pneumocole crane KS-4361, a loading capacity of 16t and the length of the boom 10m. The selection of the crane is made on the basis of the dimensions and construction of the building, the technical characteristics of the crane and the conditions for transporting the crane.

The fencing of hazardous zones is provided by a signal type of software (GOST 23407-78) with a height of 1.2 m;

Acid, temporary roads inside the building are designed by the existing concrete coating;

Temporary sidewalks are accepted by a 50mm thick 50mm thick width;

Temporary power supply is projected from the existing SER. The temporary wiring on the construction site to perform an electrical cabbage or insulated wire suspended at an altitude of 2.5m-over workplaces, 3.5m-over the passages, BM-Over drives. Jerseys with electrodelubes equip covers and hang in locking boxes. Initial premises connect power transmission using UDO devices;

The boundaries of the danger zones of the building and the crane are applied: buildings, taking into account the marks of the disassembled structures; Crane - taking into account the restriction of cargo transfer by a crane as the software and vertical;

Provides coverage of workplaces and travel frets TZD-35 spotlights

In the production of works on the organization of the construction site to be guided by the requirements of SNIP12.01-2004 "Organization of construction production", SNIP 12-03-2001 Part 1 "Labor Safety in construction", - Decree of the Government of the Russian Federation of April 25, 2012 №390 "Rules of fire regime in RF. - N123 FZ RF Technical Regulations on Fire Safety Requirements. SP 4.13130.2013 "Code of Rules. Fire protection systems" and "settlement standards for compiling construction organization projects."

The need for machines, mechanisms, equipment,devices and tools

|

N p \\ n |

Name |

technical character-ka |

mark. |

number of |

|

Pneumatic crane |

Q \u003d 16 T; L CT \u003d 10 |

KS-4361 |

||

|

Slim 4th branching |

L \u003d 5 m |

4CK-8.0 |

||

|

L \u003d 1.2 m |

SCB 1-4.0 |

|||

|

Sling TwoPetle (Universal) |

L \u003d 2.0 m |

SCB 1-4.0 |

||

|

Universal traverse |

Q \u003d 10.0 T |

Tsniyomtp R.C. 067,000 |

||

|

Electric winch with a reserve of a cable 130m |

P \u003d 0.63 T |

Each properly organized construction should have a competently composed construction documentation, which, as a rule, includes the development of such documents as a project organization project (abbreviated under), a construction organization project (abbreviated pos) and a draft work project (abbreviated PPR). All data Documents are able to ensure the security of employees during construction and installation work, ensure the right organization directly the construction of the object itself, as well as to increase the quality of the construction work performed.

To date, due to the fact that construction work began to differ in the highest severity of the need for creating and more responsible to work technological and technical solutions that are used in the work of work. That is why the main and most significant document in the system of organizational and technological training becomes the PPR document in construction - download for free, which can be at the end of this article.

This document contains a list of technological rules, requirements for safety and safety and environmental safety, including. Based on the project's work project, construction works are carried out, the necessary materials and resources are determined, the timing of work and possible risks are determined.

Who are the PPRs are being developed?

Projects manufacturing work on the construction of new structures or on the reconstruction or expansion of any facility are developed by the general contracting construction and installation enterprises. If the Peds are ordered by the General Contracting or Subcontracting Construction Organization, they can be developed by the design and technological institutions or design organizations.

It should also be noted that sometimes in carrying out large volumes of work, the PPRES is not compiled on the object as a whole, but for any particular type of work, for example, on the installation of prefabricated structures, for earthworks, on roofing works, etc. Previously, such documents had the name of the projects of the organization of work (abbreviated), but in the existing standards of SNIP 12-01-2004 instead of SNiP 3.01.01-85, they are also referred to as the PPR with the reservation that these are projects for the production of specific works. When conducting such certain types of work related to the conduct of general construction, special or installation works, the PPR are being developed by companies that are directly involved in this.

PPR composition

- Calendar work plan;

- Technological maps;

- Concrete master plan;

- Graphs of income on the object of building materials, products and equipment;

- Lists of technological equipment and mounting equipment;

- Schedules of workers in the object;

- Solutions for the production of geodesic works;

- Safety solutions;

- Explanatory note, which should contain:

- justification of solutions to implement certain types of work, including those performed in winter;

- settlements of networks of temporary engineering communications;

- activities that would ensure the safety of materials, products and structures, as well as equipment at the construction site;

- a list of mobile facilities with the calculation of the need and substantiate the conditions for their location in the construction site;

- events to protect these structures from damage, as well as environmental activities.

But it costs to note that only 4 documents remain the main in the PPR: a construction plan, a calendar plan for the production of works, an explanatory note and a technical map. Consider them in more detail.

A key document PPR in construction is definitely a calendar plan for the production of work. The success of the entire project depends on the literacy of its development to greater extent. If you speak short, then the calendar plan is a construction model model in which the sequence and timing of construction work at the facility are clearly established.

The second largest PPR document remains a building master plan (or a reduced construction plan). The quality of its preparation depends primarily to reduce the costs of organizing the construction site, which at the same time allows you to create safe working conditions for workers. Developing a construction plan, specialists take into account various ways to organize a construction site, of which the most rational is selected.

The next equally important document of the PPR is a technological card in which the most optimal methods and a sequence of performing a particular type of work are determined. In addition, labor costs are calculated here, the necessary resources are determined and the organization of labor is described. Technological maps, as a rule, include graphic and text documents, which can include both jobs that include the front of the work and the boundaries of the plots to which the object is divisible. In principle, technological maps can be three types:

- typical without reference to specific objects;

- typical with reference to typical objects;

- individual with reference to a specific project

And the latest important element of the PPR can be called an explanatory note, in which, as mentioned above, all sorts of labor protection measures are indicated, the conditions and complexity of construction are determined, the presence of warehouse premises and temporary structures are substantiated. In addition, the explanatory note provides technical and economic indicators of construction.

Download PPR for construction you can.

Extraction out

MDS 12-39.2008

Methodical example of a draft work of work (PPR) on the installation of a panel high-altitude house Introduction

The project manufacturing project consists of a general section and technological maps on the installation of the standard floor, the second floor on the monolithic overlap, the attic and the machine room.

Technological card on the installation of the standard floor contains the full composition and amount of information necessary for the production of work. The remaining technological maps in order to exclude repetitions contain only the features inherent in these stages of work.

The draft work project consists of textual and graphic parts. The graphic portion is represented by the schemes of the lines, the location of the fence of the hazardous zone and safety devices, alignment of containers and inventory at the overlap, sequence of flooring, panels on overlapping and temporary fastening of prefabricated elements.

This methodical document is intended to provide project, design and technological and building organizations assistance in developing a project for the installation of work on the installation of a panel high-rise residential building.

The methodological document is based on the results of the works of TNIIIMTP and other design and technological institutions, as well as a summary of the practical experience of the installation of panel high-altitude residential buildings by the Moscow construction organizations.

1. Explanatory note

The project production project was developed on the installation of the above-ground part of the individual residential high-altitude panel house of the tower type. Such a house is designed, as a rule, with the first non-residential floor and overlap - from the monolithic reinforced concrete.

The plan of the house is a rectangle, close to the square, area, as a rule, from 750 to 1500 m. The house height does not exceed, as a rule, 90 m or 30 floors.

The prefabricated elements of the house, mainly - slabs of overlaps and coatings, the panel of the exterior and inner walls and partitions. Wall panels and partitions without openings and with openings. Internal panels, usually bearing, outdoor panels - self-supporting or mounted. Panels - enlarged (one or more rooms size), complex (with installed window and door blocks, with insulation and roofs on the panels of coatings).

The main material of the panels is various types of reinforced concrete. The exterior wall panels are single-layer or multi-layered. The bearing panels of the inner walls and partitions are made of severe reinforced concrete, and nonsense - from light concrete. The ceiling plates are made of pre-stressed reinforced concrete in the form of flat solid or hollow, with channels for wiring, with mounting holes for temporary mounting plates and safety devices.

The size of the panels usually do not exceed 20 m, walls - floor, overlap - on the room, the thickness of the panels - up to 350 mm, weight - up to 5-8 tons.

The project manufacturing project provides for the installation of prefabricated elements of the standard floor, attic and machine room, and also discusses the features of mounting work on monolithic overlap.

Mounting work is made using free-standing and dotted tower tower cranes Type KB-473 produced by JSC Height (Rzhevzhe), KB-581 produced by OJSC "Mechanical Plant" (SANKT-Petersburg) and others.

The project manufacturing project was drawn up in accordance with the recommendations of MDS 12-81.2007 and MDS 12-29.2006 and contains general typical solutions to mount the above-ground part of a residential building. The project was developed taking into account the current requirements for the production of installation work, namely, to the installation of prefabricated elements mainly from vehicles, and with maximum combination of installation work with internal general construction and special work, including assembling elevators and finishing work.

Such necessary sections of the project project manufacturing, as a building master plan and a calendar construction plan, are not given here due to the fact that their development does not have features for this object and does not represent difficulties.

When developing a methodological example, materials of the organizational and technological and development and design developments of the Central Committee and other institutions in the field of construction, as well as regulatory, methodological and reference documents are used.